Electronics – Closed Loop Motor

Follow these instructions if you’re assembling a Vortex rotary axis kit which utilizes a closed loop motor with two motor cable connections.

You can refer to the video below for a general overview of the setup process. Scroll down for detailed, step by step directions with images.

Wiring Installation

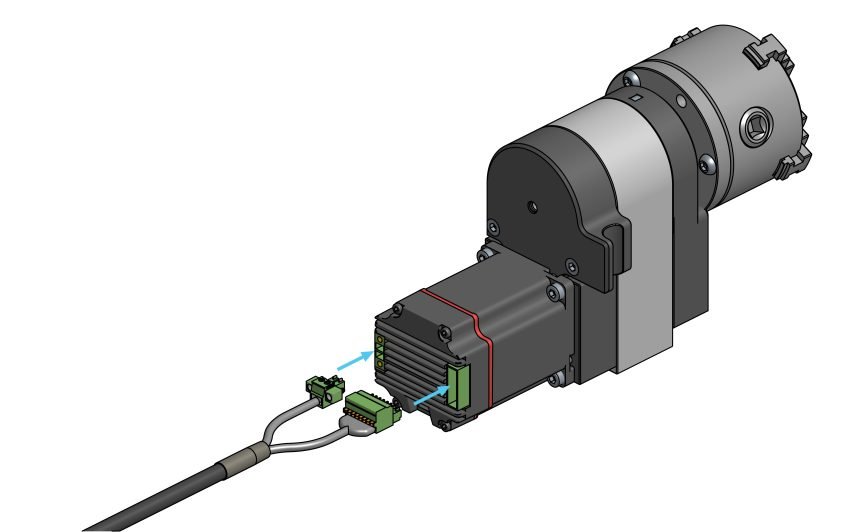

Grab the motor cable included in the Vortex rotary axis kit and plug the two green connectors into their respective plugs on the rear of the closed loop motor. Tighten the two small screws on the 2 pin power connector using a small flathead screwdriver.

Plugging in connections on the closed loop motor

For the SLB-EXT:

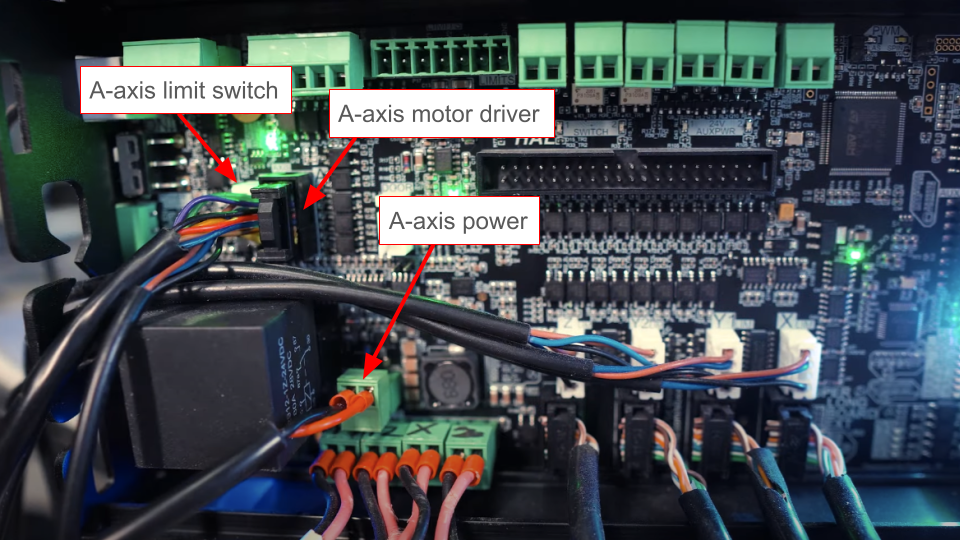

Plug in the power, limit switch and driver connectors into their appropriate locations as shown below.

A-axis connections to the SLB-EXT (AltMill)

For the SLB:

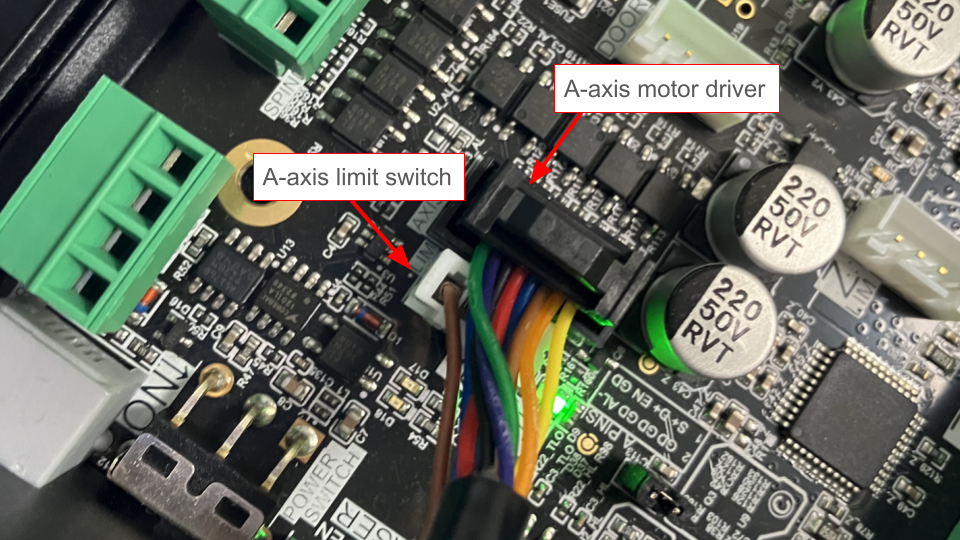

Make the motor driver and limit switch connections as shown.

A-axis connections to the SLB (LongMill)

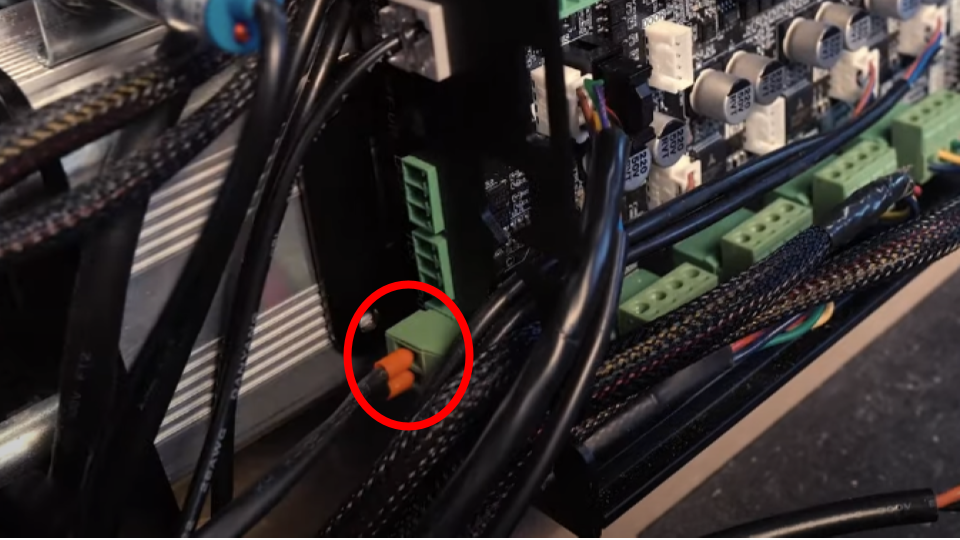

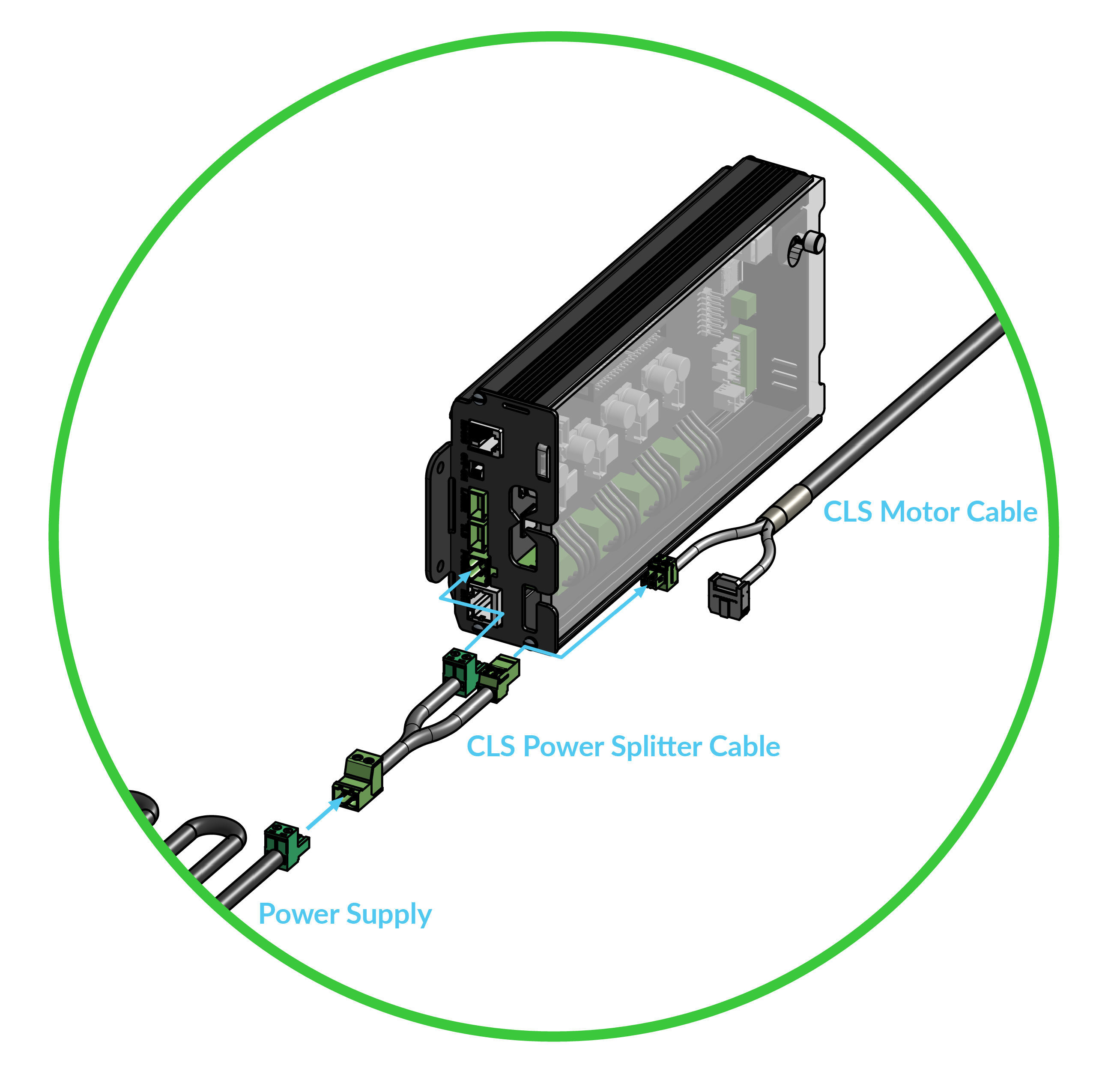

Plug the power splitter into the external power supply that comes with your controller.

Power splitter for the SLB A-axis connections

The two green connectors will be distinctly different, so you can make the appropriate connections to power the controller and the A-axis.

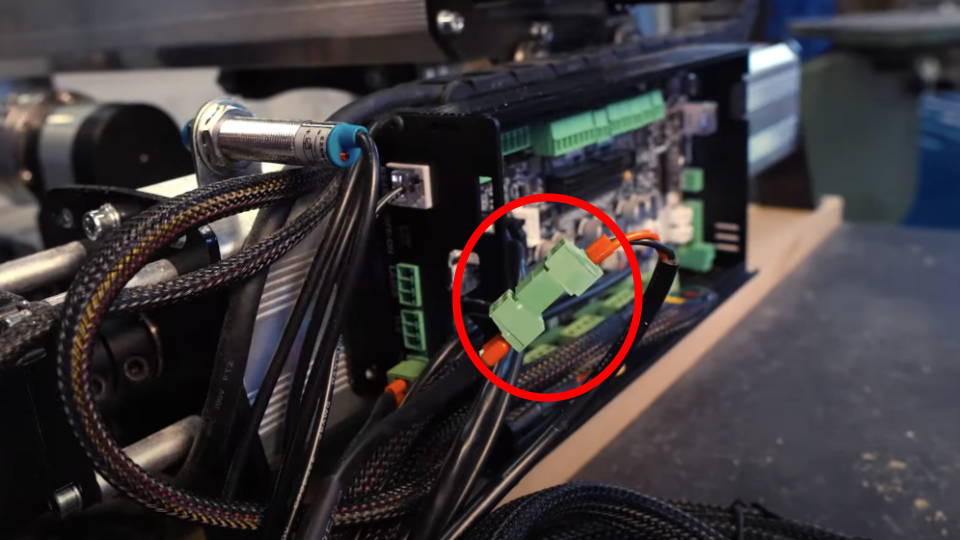

Connect power splitter to POWER input on the side of the SLB

Plug the other end of the splitter to Vortex power connector

Power splitter wiring overview

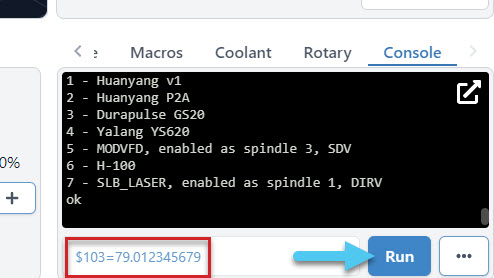

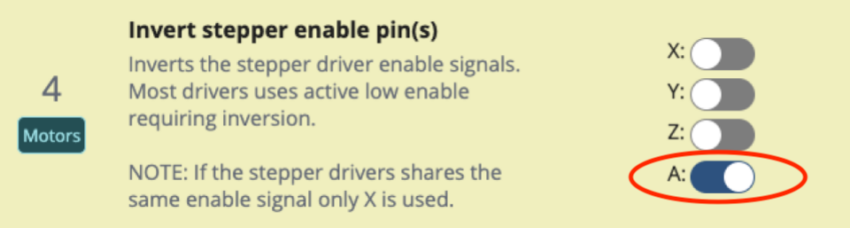

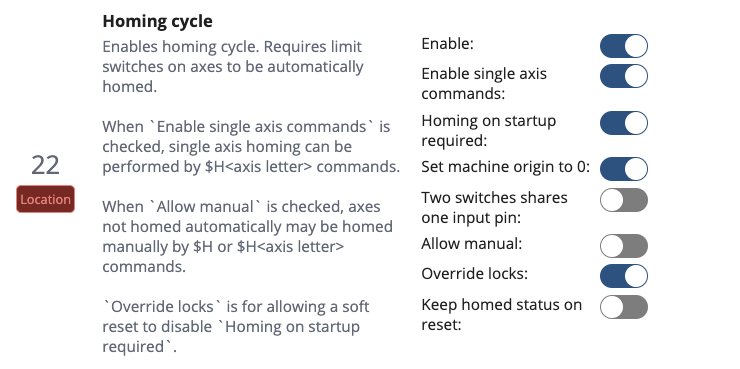

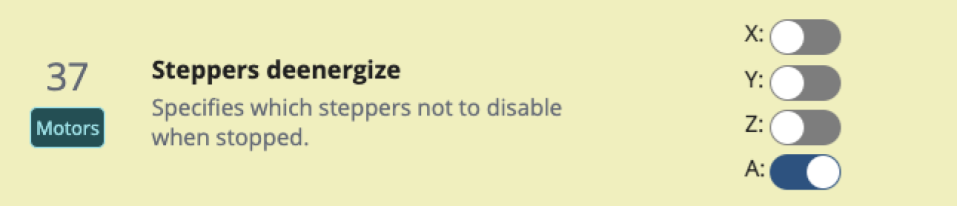

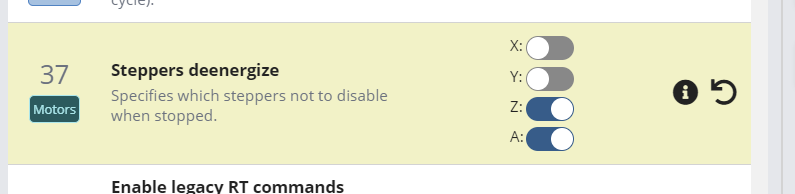

Firmware Settings

gSender 1.5.0 and above

gSender 1.4.12 and below

Motor Check

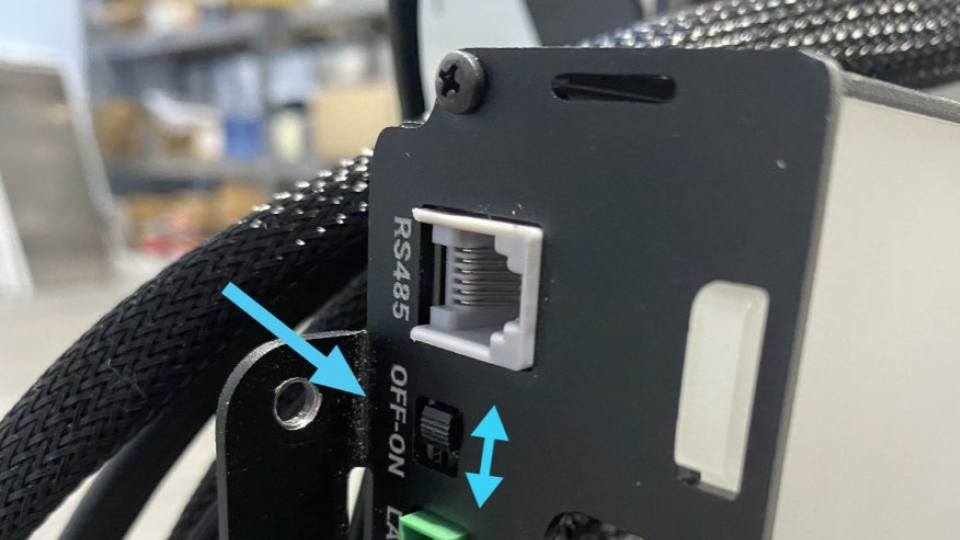

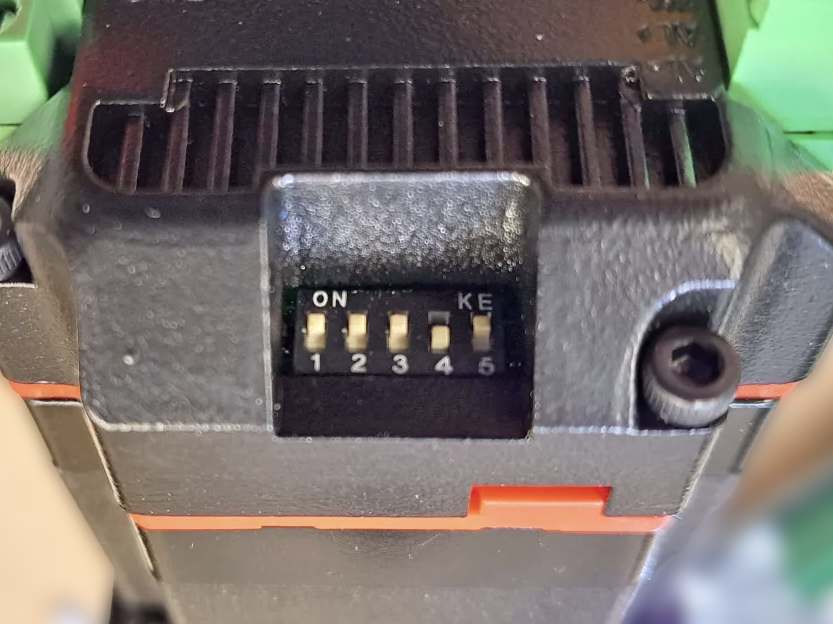

Check the dip switches on the back of the closed-loop stepper motor to ensure they are set to the correct settings. Use a small tool to seat the small switches. The switches should be:

1 – ON, 2-ON, 3-ON, 4-OFF, 5-ON

Vortex Closed-Loop Dip Switch Position

Congratulations! A job well done, you’ve completed the assembly and firmware steps. Take a deep breath, we are almost ready for a test drive.