General Safety

When you’re working with your CNC machine, it’s easy to forget that the noise and dust in the air can be just as dangerous as an end mill. Dust from wood, plastics, or other materials can irritate your respiratory system over time, even if you don’t notice it right away. On top of that, the noise from tools like routers and vacuums can quietly damage your hearing without you realizing how quickly it happens. The good news is, with a few simple precautions—like wearing proper masks and ear protection—you can minimize these risks and keep your hobby enjoyable and safe for the long run.

Below are guidelines we strongly recommend to help prevent injury and protect your ears, eyes, lungs, limbs and phalanges for years to come.

- Stay alert – Never operate the machine when tired, distracted, or impaired.

- No loose clothing or jewelry – Keep long hair tied back and avoid anything that could get caught in moving parts. Wear proper footwear.

- Protect your hearing – CNC machines combined with dust collection systems can be very loud. Use earplugs and/or over-the-ear protection.

- Protect your lungs – Always wear a dust mask or respirator (minimum N95). Some materials release toxic dust or fumes—check the MSDS (material safety data sheet) for your material.

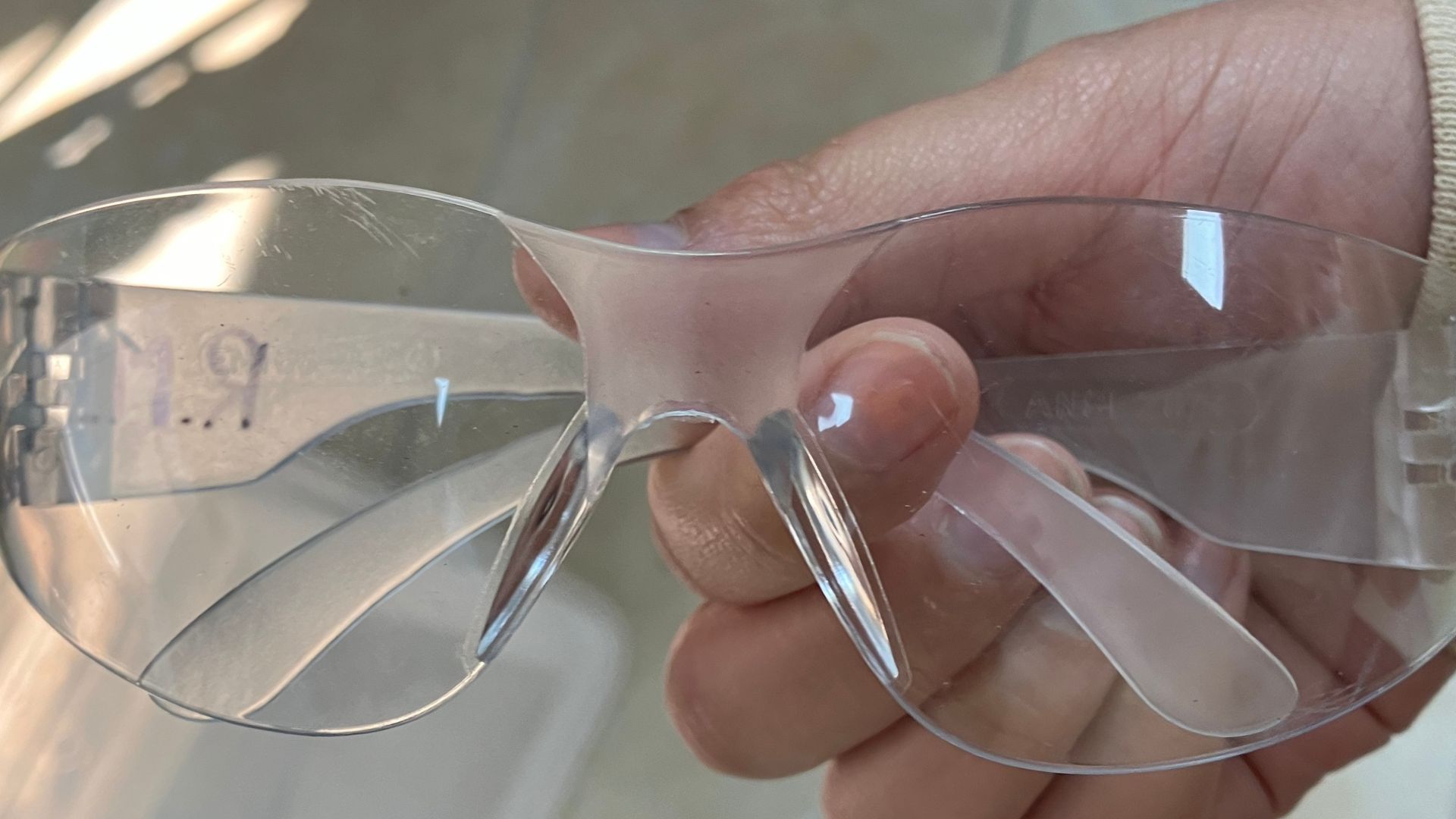

- Protect your eyes – Chips and fine dust can fly unpredictably. Safety glasses or goggles are a must.

- Don’t leave the machine unattended – Unexpected movements or tool failures can happen quickly.

- Handle tools and materials carefully – Cutting tools can cut skin or shatter if damaged. Materials may ignite during cutting or disposal, especially in dust collection bins. Avoid collecting metal dust/chips with wood dust.

- Dispose responsibly – Follow local rules for safe disposal of cutters, dust, and materials.

Operation Guidelines

CNC machines are powerful and fast machines that can cause significant harm if you do not take safety precautions as necessary. To give you an idea of what could occur, we talked to a CNC expert about their close-calls with their machine:

“A big hazard is how fast the machine can run, especially during rapid movements. The machine could be moving fairly slowly for a portion of the job, but then suddenly jerk to a different position. This is especially dangerous if you were trying to feel the grain of the workpiece or hold down the workpiece with your hands, even for just a moment… Best scenario is to never put your hands there in the middle of a job, but if you really need to, pause the job or use a push stick to hold things temporarily.”

- Never lean on or rest hands on the machine during operation.

- If you need to adjust the workpiece, pause the job and use a push stick or clamp instead of your hands.

- Always assume the machine could move suddenly—stay clear of its path.

- Carefully handle tools and materials. Cutting tools can shatter or cause damage if they’re not in good condition, and could cut you during handling.

- Be aware of safe disposal measures for your cutters and materials. Materials could ignite during cutting, within your dust collection system, or even spontaneously especially if mixed in with other chemicals or oils when disposed. Avoid using dust collection when cutting metals, as the hot metal could ignite existing sawdust in your disposal bin.

To investigate more safety guidelines, check out the Important Safety section.