CNCs can create a lot of mess just like many other shop tools. Think about the chips and dust you can create drilling a single hole or cutting a piece of wood in half and then stretch that out over hours of constant cutting on a CNC machine. Not only can this add up to a very large mess, but it’s also not good for your health or your CNC’s health, since important parts can get gummed up with dust over time and impact cutting performance.

This is where a ‘dust collection’ system can help out. CNC dust collection systems are very similar to what you’d normally see in a woodworkers shop. Starting at the cutting head you have a:

- Dust Shoe which tries to contain the dust where the cutting is happening

- Hose that the dust can flow along

- Some type of Vacuum System that creates the suction to carry the dust away from the dust shoe

There are also other options not covered on this page like building an enclosure for your CNC or running it in an open-air environment. These should still be used alongside a dust collection setup, but can be fine short-term to reduce setup complexity.

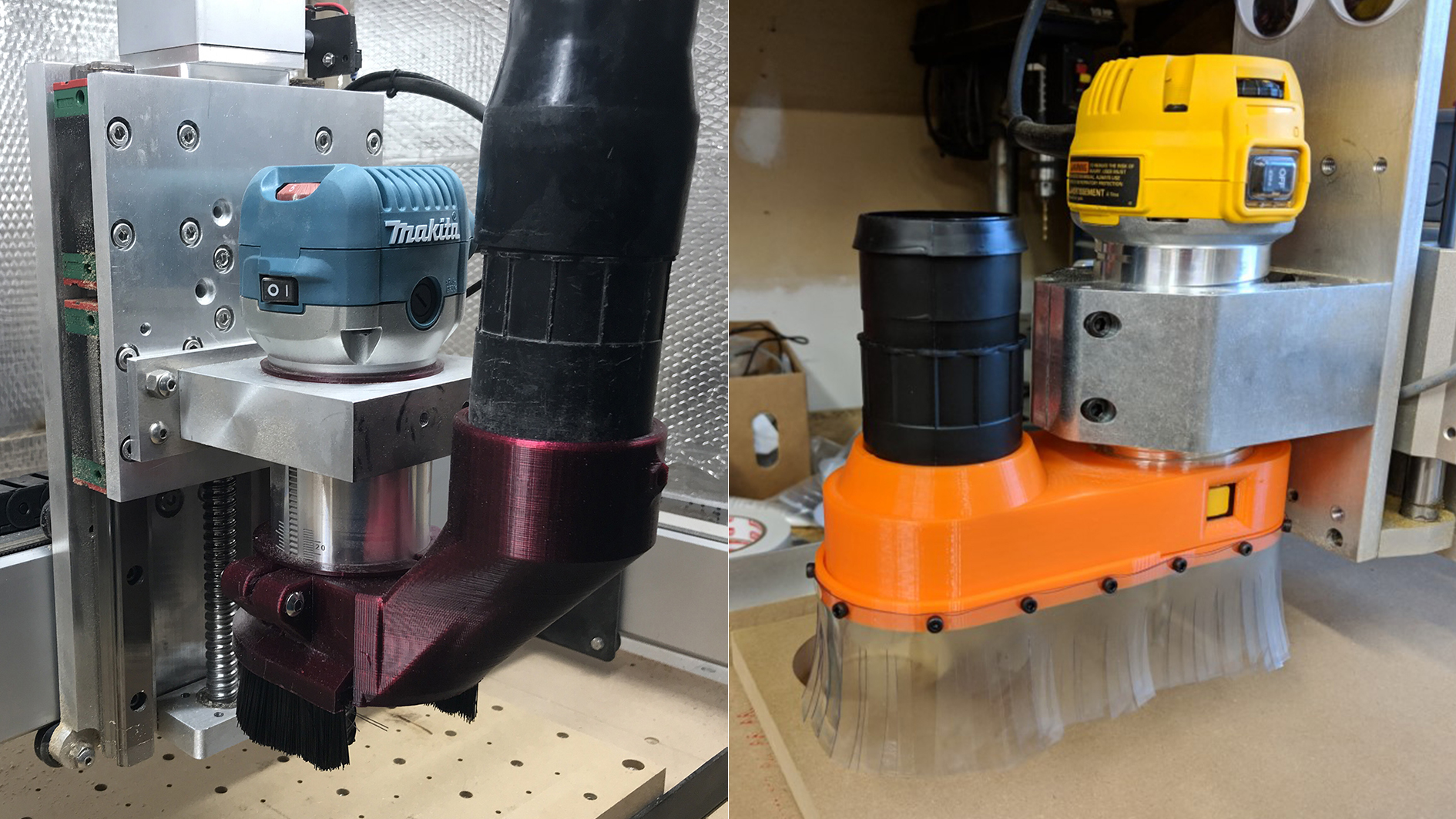

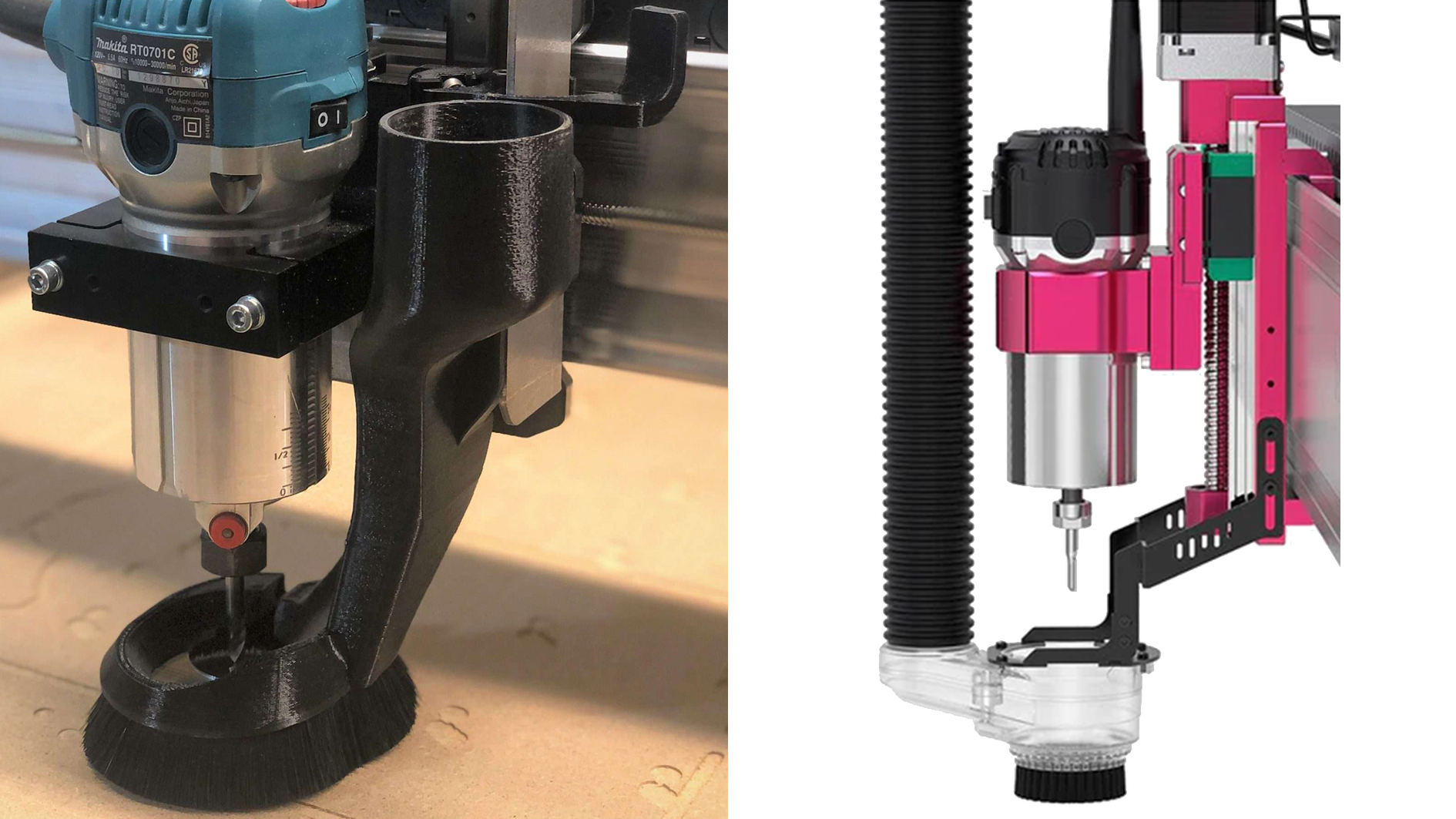

Dust Shoes

A dust shoe is basically a fancy vacuum attachment for your CNC machine, it stays near the cutter to stop chips and fine dust from flying away while the vacuum system pulls it all away. This is good because it:

- can give you cleaner cuts with the debris out of the way

- reduces maintenance since dirt build-up can cause premature wear on many CNCs

- saves you time cleaning up what you’d have to clean anyway

- keeps your shop air cleaner which is safer for your lungs

Fixed vs. Adjustable Dust Shoes

The design of your dust shoe can greatly affect how well it collects dust for you particular application. There are hundreds of different designs for dust shoes, however, one of the largest differentiators is whether it is fixed or adjustable. These two styles are also sometimes referred to as Z-axis dependent / bound / tethered vs. Z-axis independent / unbound / free.

Whether a dust shoe is fixed or adjustable depends on how it’s mounted:

- A fixed-style dust shoe is mounted to the Z-axis or the router body on the CNC. This means that when the Z-axis moves up or down during cutting the dust shoe moves up and down with it.

Source – https://community.carbide3d.com/t/hall-of-dust-shoes/7717/20?page=2, https://maniacallabs.com/2019/02/25/CNC-dust-boot-for-dewalt-router/ - An adjustable-style dust shoe is typically mounted to the X-axis of the CNC. This means that it never moves unless you manually change it’s position, allowing the Z-axis to raise and plunge during cutting while the dust shoe stays in the spot you set it. It can be held in place with strong magnets for quick and easy adjustments as in the left image, or secured with a couple bolts as shown in the right image below.

Source – https://www.nymolabs.com/products/CNC-dust-shoe-only-for-nbs-6040-nbx-5040

For general purpose cutting, we recommend using an adjustable dust shoe as it is significantly better at collecting dust and debris, and relies less on how powerful your vacuum system is. It’s also much better suited toward flat or sheet material which is the type of material that’s most commonly used by hobby CNC users for sign-making and v-carving.

| Fixed | Adjustable | |

| Pros |

|

|

| Cons |

|

|

| Build Name | Description | Link |

|---|---|---|

| Articulating Dust Shoe | User-created articulating dust shoe design | Forum Discussion |

| 3D Printable Automatic Dust Shoe (Stepper Motor) | 3D printable dust shoe driven by a stepper motor | Forum Discussion |

| AutoDustBoot Version 2.0 | An improved automatic dust boot solution | YouTube Video |

Hose Size

Your shop vac or dust collector will come with a hose of a certain diameter – so consider using this as the basis for the rest of your system. It’s usually not recommended to adapt between small and large hoses since it generally make a large impact on suction performance. Some other indicators you’d want to look for in your system would be:

- CFM (cubic feet per minute): this denotes the amount of air your vacuum can pass through. The higher the CFM, the greater volume of dust you can move. You will want a higher CFM rating if you are cutting a large amount of material.

- Suction power (sometimes called Water Lift, Static Lift, Static Pressure…): this indicates how fast the air is moving through the system. The higher your suction is, the harder the dust is pulled through your dust shoe and hose. You will typically want a higher suction vacuum if you are cutting heavier materials like metals, need to draw chips out of narrow cuts, or are using a fixed-style dust shoe.

Dust collectors for example typically have higher CFMs but lower suction power, and thus are better suited to larger diameter hoses. Using a smaller diameter hose can constrict airflow and reduce its efficiency. Shop-Vacs, on the other hand, have smaller CFMs but higher suction power. These types of vacuums work well with using smaller diameter hoses.

Depending on the design of your dust shoe, you may need an adapter that joins dust shoes and hoses with different diameters so just be sure not to change hose size by too much. You may also want to opt for a hose that will keep static buildup along it’s length to a minimum in which case more specialized options exist such as the 36mm antistatic hose from Festool.

Hanging Your Hose

It’s best practice to have the dust collection hose hang above the dust shoe so that it doesn’t put any pressure on the router or get caught up in your work. You can simply hang it from the ceiling or use a more advanced solution like an articulating arm. Make your own, or grab one from Etsy!

| Title | Duration | Link |

|---|---|---|

| Easy CNC Swing Arm | 3 min | Watch Video |

| Custom Dust Collection Swing Arm | 18 min | Watch Video |

Choosing a Vacuum System

Your dust shoe and hose will need a source of suction. Most times an existing dust collector or Shop-Vac with a cyclone separator will be able to fit the bill since these systems are set up to run for many hours and provide reasonable suction. You may want to check your system’s CFM and suction lift specifications to see if they would work well with your dust shoe and hosing.

1. Shop Vac

A shop vac is a versatile, high-suction device primarily designed to pick up larger particles, such as wood chips, sawdust, and even liquid spills. It is the most common type of dust collection used in the hobby CNC space. With many affordable options available at many large box stores, you can get setup and running right away with a shop vac. You can move it around the CNC or build a dedicated space for it.

| Model | Description | Link |

|---|---|---|

| WEN VC9209 | 10-Amp 9.25-Gallon 6.5 Peak HP Wet/Dry Shop Vacuum | Buy Here |

| Uline Wet/Dry Vacuum | 10 Gallon, Stainless Steel | Buy Here |

| Rigid Wet/Dry Vacuum | 10 Gallon, 6HP | Buy Here |

| Vacmaster Professional | 8 Gallon, Hepa Filter | Buy Here |

| Hercules | 12 Gallon, Dual Hepa Filter, Noise adjustable | Buy Here |

Adding a Cyclone to your shop vac can also drastically reduce the amount of filters your shop vac or dust collection system uses. This ‘second stage’ works by using centrifugal force to separate most dust and debris into a bin below while the lighter, cleaner air is directed upwards, often passing through a secondary filter for finer particles. This process improves efficiency, reduces filter clogging, and extends the lifespan of the dust collection system.

Many users will make their own, or you can purchase a pre-made one.

| Video Title | Duration | Link |

|---|---|---|

| How do Cyclone Dust Separators Work? | 5 min | Watch Here |

| Adding a Dust Separator to a Shop Vac | 12 min | Watch Here |

| Dust Cyclone Separator Cart | 15 min | Watch Here |

2. Dust Collector

A dust collector is designed to capture greater volumes of dust and wood chips typically generated from large CNCs and woodworking tools. It is a more powerful and specialized system compared to a shop vac. It is often stationary and connected onto multiple tools.

| Model | Description | Link |

|---|---|---|

| POWERTEC | 1 HP Dust Collector with 1 Micron Dust Collector Bags | Buy Here |

| WEN | 5.7 AMP 660 CFM Rolling Dust Collector | Buy Here |

| Grizzly G0944 | 1-1/2 HP Wall-Mount Dust Collector with Canister Filter | Buy Here |

| Grizzly G0548ZP | 2 HP Canister Dust Collector w/Aluminum Impeller | Buy Here |

Choosing the System

- Use a Shop Vac if you need portability and versatility for general cleanup or larger wood particles and debris. Most people start here as it is most economical and simple to setup and get going.

- Choose a Dust Collector if you have a dedicated woodworking shop with stationary tools and need continuous dust collection. If you are already a woodworker and have a shop, you may already have one of these.

Features Comparison

| Feature | Shop Vac | Vacuum w/ Cyclone Attachment | Dust Extractor |

|---|---|---|---|

| Best For | Small to medium CNCs, shorter jobs, spot cleaning, larger debris | Capturing large volumes of dust and debris before it reaches the filter | Large CNCs, long/large jobs, fine hazardous dust from sanding |

| Suction Power | High suction, lower airflow | Moderate to high suction, depending on base vacuum | Moderate suction and airflow |

| Filtration | Basic or HEPA; limited fine dust capture | Improved dust separation; filters last longer | HEPA filtration for very fine dust |

| Airflow (CFM) | 100-200 CFM | 100-400 CFM (based on vacuum used) | 400-1000 CFM |

| Portability | Portable | Fixed or portable; may require more space | Often fixed, tool-compatible |

| Hose Size | 1.25–2.5 in. | 2–2.5 in. (varies by vacuum) | 4–6 in. |

| Dust Shoe | Compatible with smaller, lightweight shoes | Works well with most CNC dust shoes | Designed for larger, high-capacity dust shoes |

Each of these systems has its strengths, costs, size, and power requirements. Often woodworkers start with a simple shop vac and build up to a combination of shop vac & cyclone or a dust collector system. Add in a dust extractor to your shop, and you’ve created an optimal setup for a safer, cleaner workshop.

User Setups

You can customize your shop to have a simple shop vac with hose hanging above your CNC, upgrade to a 2 stage system and add a cyclone, or build a cart for portability. Upgrade further to a wall mounted dust collection system, and run it to each tool in your shop. You can even add blast gates to your system, activated manually or automatically! Check out this section to see what other users have come up with for their own setup

| Video Title | Duration | Link |

|---|---|---|

| Dust Collection for Beginners | 10 min | Watch Here |

| Attic Based & Voice Activated System | 15 min | Watch Here |

| Wall Mounted Dust Collector Setup | 6 min | Watch Here |

| Cart for Shop Vac and Cyclone | 2 min | Watch Here |

| Upgrade from Shop Vac to Dust Collection | 4 min | Watch Here |

| Advanced Setup with Blast Gates for Each Tool | 11 min | Watch Here |

| Pairing the best Dust Collector with a CNC | 13 min | Watch Here |

| 5 tips to improve CNC dust collection DIY | 6 min | Watch Here |

Dust Safety

When it comes to CNCing, it’s easy to forget that dust in the air can be just as dangerous as an end mill – this is why we bring it up in the MK2 Manual. Dust from wood, plastics, or other materials can irritate your respiratory system over time, even if you don’t notice right away. This can lead to a chronic cough, chest pain, runny nose, headaches, bronchitis and more. This is why it’s good to take precautions – like wearing a proper mask – to minimize these risks and keep your hobby enjoyable and safe for the long run.

To give some more details – in the woodworking hobby, dust is classified into categories—L (low-risk), M (medium-risk), and H (high-risk), based on the type of material and associated health risks.

- L-Class (Low Risk)

- Minimal health risk but requires basic dust control.

- Softwoods (pine, cedar) – respiratory irritants.

- Plastics – sanding dust can cause irritation.

- M-Class (Medium Risk)

- Higher respiratory hazards; requires enhanced filtration.

- Hardwoods (oak, beech) – fine dust can trigger allergies and long-term issues.

- Plywood/MDF – releases formaldehyde and chemicals when cut or sanded.

- Painted/coated surfaces – may contain toxic compounds like lead. Use caution when surfacing an old painted piece of wood for example.

- H-Class (High Risk)

- Carcinogenic/toxic materials; requires specialized protection.

- Silica dust (from concrete, tile, stone) – leads to silicosis if inhaled. Be careful carving an old tile for example.

In general, you can protect yourself on 3 basic levels:

- Level One – Prevent dust from entering your body. Your nose and mouth should be covered with a high quality dust mask or respirator with a minimum rating of N95.

- Level Two – Grab the dust at it’s source. Your project should have a good dust collection system, to remove as much dust at the source as possible, before the particles have the chance to become airborne. This type of protection ‘collects’ the dust at the source.

- Level Three – Clean the air. Your workshop can add more protection against those fine particles by using a dust extraction system to catch any particles your dust collector misses. This type of protection ‘extracts’ fine dust particles from the air in your shop.

Regularly cleaning work surfaces, machines, and the floor will also help minimize any dust that could be kicked up by new projects. Working with a door open or an exhaust fan in a well ventilated area is also a great way to reduce your exposure to hazardous fine sawdust materials. We recommend using at least level one and two while operating your CNC.

To investigate more safety guidelines, check out the Important Safety section!

Adding a Dust Extractor

A dust extractor is a specialized type of vacuum designed to capture fine, hazardous dust, often with more precise filtration systems than typical shop vacs. Dust extractors are especially useful for capturing finer particles, such as those from sanding or cutting engineered woods, concrete, or other materials that release smaller, respirable dust.

Note: A dust extraction system is used in your shop, not on your CNC and must be used alongside a dust collection system

- Power and Filtration: Dust extractors typically come with HEPA filtration or very fine filters capable of capturing particles as small as 0.3 microns, which is essential for protecting respiratory health.

- Airflow (CFM): Dust extractors usually have moderate CFM, around 100-200, similar to shop vacs, but the focus is on high-quality filtration rather than raw suction power. Many models also have automatic filter-cleaning features.

- Portability: They are generally portable and compact, making them easy to connect directly to handheld tools (like sanders or circular saws) for on-tool dust collection.

- Best Use: Dust extractors are best suited for capturing fine dust particles from sanding, concrete grinding, or other tasks that create hazardous, respirable dust.

| Model | Description | Link |

|---|---|---|

| WEN AF1270 | 4.2-Amp 3-Speed Remote-Controlled Industrial-Strength Air Filtration System | Buy Here |

| Fein 9-20-27 | Turbo Vacuum, 5.8 Gallon, HEPA filter | Buy Here |

Sawdust Recycling

This is a bonus section at the end of this page that we wanted to write for some fun. You might not know this, but regular sawdust that you might collect while carving has a surprising number of useful applications. Mix with wax for a camping fire starter or mix with wood glue to make art. Mulch your flower beds or make a bed for your livestock. What ever you do, don’t throw it all away!

- Wood Filler: Combine sawdust with wood glue to fill in gaps or cracks in woodworking projects. You can often match the colour of the project if you use sawdust from that project.

- Absorbent Material: Sawdust soaks up spills well, making it useful for cleaning up oil or paint spills.

- Mulch: Sawdust can be spread around plants to retain moisture and suppress weeds. Just be cautious with hardwood sawdust, as it can deplete nitrogen from the soil.

- Compost: Mix sawdust with other organic matter to create a rich compost. Be mindful of the wood type; avoid sawdust from treated wood.

- Pathways: It creates a soft, natural-looking walkway and prevents muddy paths in gardens.

- Animal Bedding: Use sawdust as bedding for small animals, chickens, or livestock. Be careful with aromatic woods like cedar, which might irritate some animals.

- Wood Stain: Darker sawdust can be boiled in water to create a natural stain.

- Molded Wood Projects: Mixing sawdust with resin or glue can create a wood-based composite for small molded items.

- Fire Starters: Mix sawdust with wax to create fire starters, or simply use small piles of sawdust on kindling. Great to take camping!

- Pathways for Erosion Control: Spread on slopes or muddy areas to reduce erosion.

- Ice Melt Substitute: In winter, use sawdust on sidewalks or driveways for traction instead of salt. Good idea Eh!?

Collect different types of wood sawdust to match your projects, or make a new project with your freshly made sawdust. If you do want to throw it all out, the last short video is a great way to make smaller bags.

| Title | Description | Length | Video Link |

|---|---|---|---|

| Save Sawdust in Tins for Glue | Collect and store different types of sawdust in separate tins. Mix with glue to use for repairs in woodworking projects. | Short | Watch Video |

| Reuse Sawdust for Art | Repurpose sawdust in art projects, adding unique textures or effects to artwork. | Short | Watch Video |

| 41 Creative Uses of Sawdust | Amazing ideas for using sawdust around the homestead and garden, from composting to fire starters. | 5 min | Watch Video |

| Sawdust Flowerpot Project | Turn scrap sawdust into a project to sell by creating a flowerpot. | 12 min | Watch Video |

| Clear Your Lungs After Inhaling Dust | Understanding effective methods to clear your lungs after inhaling dust is crucial for maintaining respiratory health | 9 min | Watch Video |

| Compact Sawdust Bags | Compress sawdust bags to make them more compact, saving space and making them easier to store or dispose of. | Short | Watch Video |

Congrats! You are now all up to speed on types of dust collection systems available to the hobby CNC market, how to put them to use and even how to use all that sawdust you will be creating. Be safe, be healthy, & have fun!!