All CNCs read g-code, but it can come in different formats. To ensure the g-code is tailored for your machine, you must apply a post-processor.

We’ve put together a simple table which shows popular CAM programs and their AltMill-compatible post-processors.

Post-Processor Table

| CAM Software | Post-Processor |

| Vectric Cut2D, Vectric VCarve, Vectric Aspire | GRBL (mm), GRBL (in) |

| Carveco Maker, Carveco Maker+ | UGS GRBL |

| Fusion 360 | GRBL |

| Easel, Easel Pro | No selection required |

| Carbide Create | GRBL |

| CAMLab | No selection required |

| ESTL Cam | No selection required |

| FreeCAD | GRBL (mm) |

| BobCAD/CAM | Custom: https://forum.sienci.com/t/cad-cam-software-post-processors/436/3 |

| Inventor CAM | GRBL (mm) |

Vectric VCarve

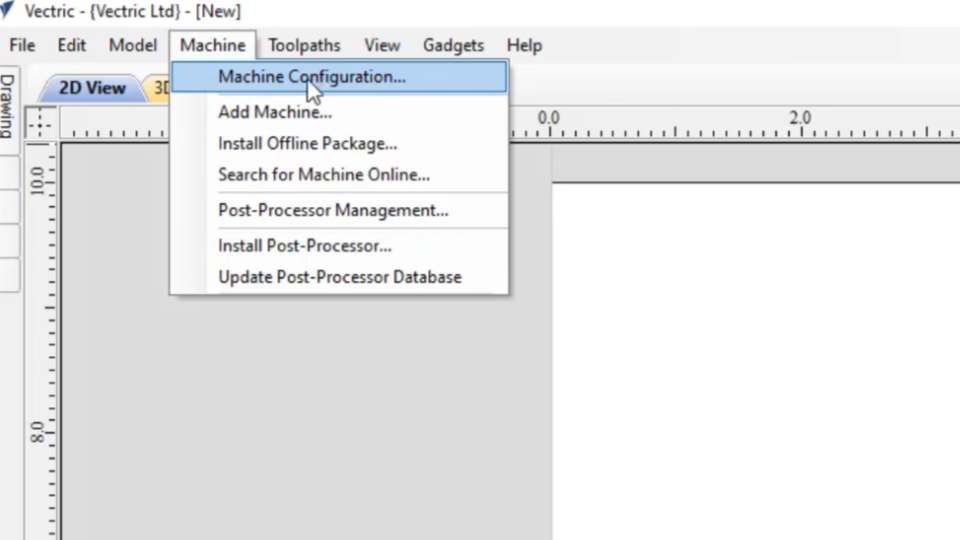

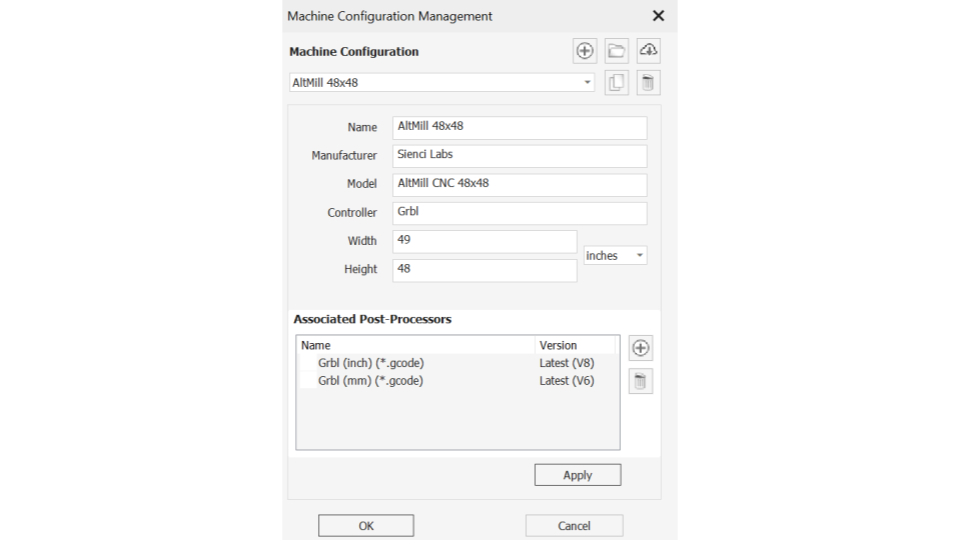

If you are using Vectric VCarve, you can create a custom machine configuration file for your AltMill. Go to Machine, and in the drop down select Machine Configuration.

Please refer to the image below to fill out the configuration. For the latest version of VCarve, please input all the AltMill accelerations as 1500 mm/s².

Fusion 360

To avoid potential issues with Fusion 360, we also recommend you make the following checks to your post-processor:

- Change the ‘Safe Retracts‘ to “Clearance Height” and NOT “G28”. It will be obvious that you have this on if you don’t have limit switches or forget to home your machine and a the start of the job your bit plunges suddenly really deep into your material.

- Output M6 set as “No” (unless you plan to set up tool changing)

- Output Tool Number set as “No” (unless you plan to set up tool changing)