The LongMill is a 3-axis CNC router which falls under the category of ‘CNC machine’. This is a category of machines that receive and execute incoming commands from a computer. What makes a CNC 3-axis is the ability to move in three independent directions. For the LongMill, these directions are all straight-line motions. If you remember back to high-school geometry or math, these would be called X, Y, and Z directions, enabling it to cut 3D objects in 3D space.

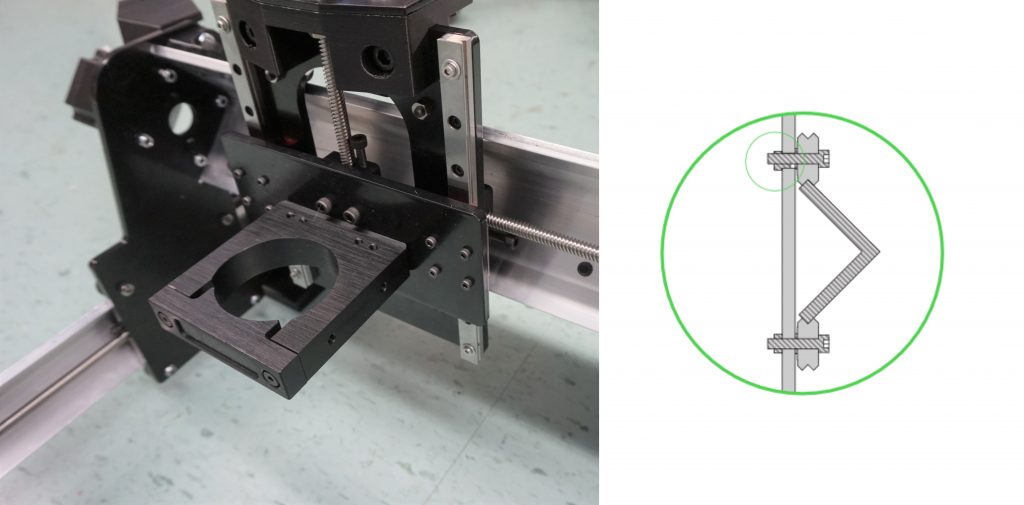

The movement system on the LongMill uses wheels and screws for simple and affordable motion. The v-shaped wheels riding on the edge of the extruded aluminum profiles brings affordability yet remain accurate, and the screws bring the power. Industrial CNC milling machines take all these concepts a step further. This can mean introducing more directions of movement, more powerful and repeatable drive systems, and sometimes much larger build volumes as well.

CNC routers are quite capable when it comes to manufacturing a variety of objects. Most can handle cutting into materials like: wood, plastic, foam, machining wax, and similar soft material variants. A handful can also handle cutting soft metals like aluminum, brass, and copper and even harder materials like stone, tiling, and high-carbon steels. These CNC routers start to overlap with the more industrial CNC Milling Machines.

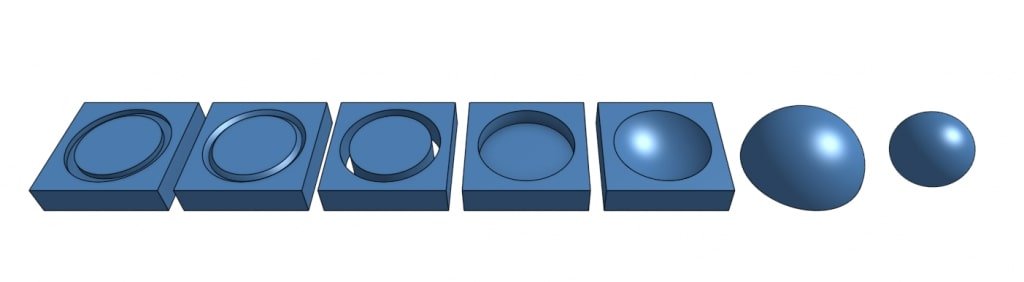

Jobs can vary from simple surface engravings or v-carving to cutting line profiles, pocketing, carving reliefs, or even making multi-orientated jigs for cutting from many sides. Most of the time, regular projects can be made with simple 2D cuts (shown with the first examples) and can be designed with simple drawings or pictures.

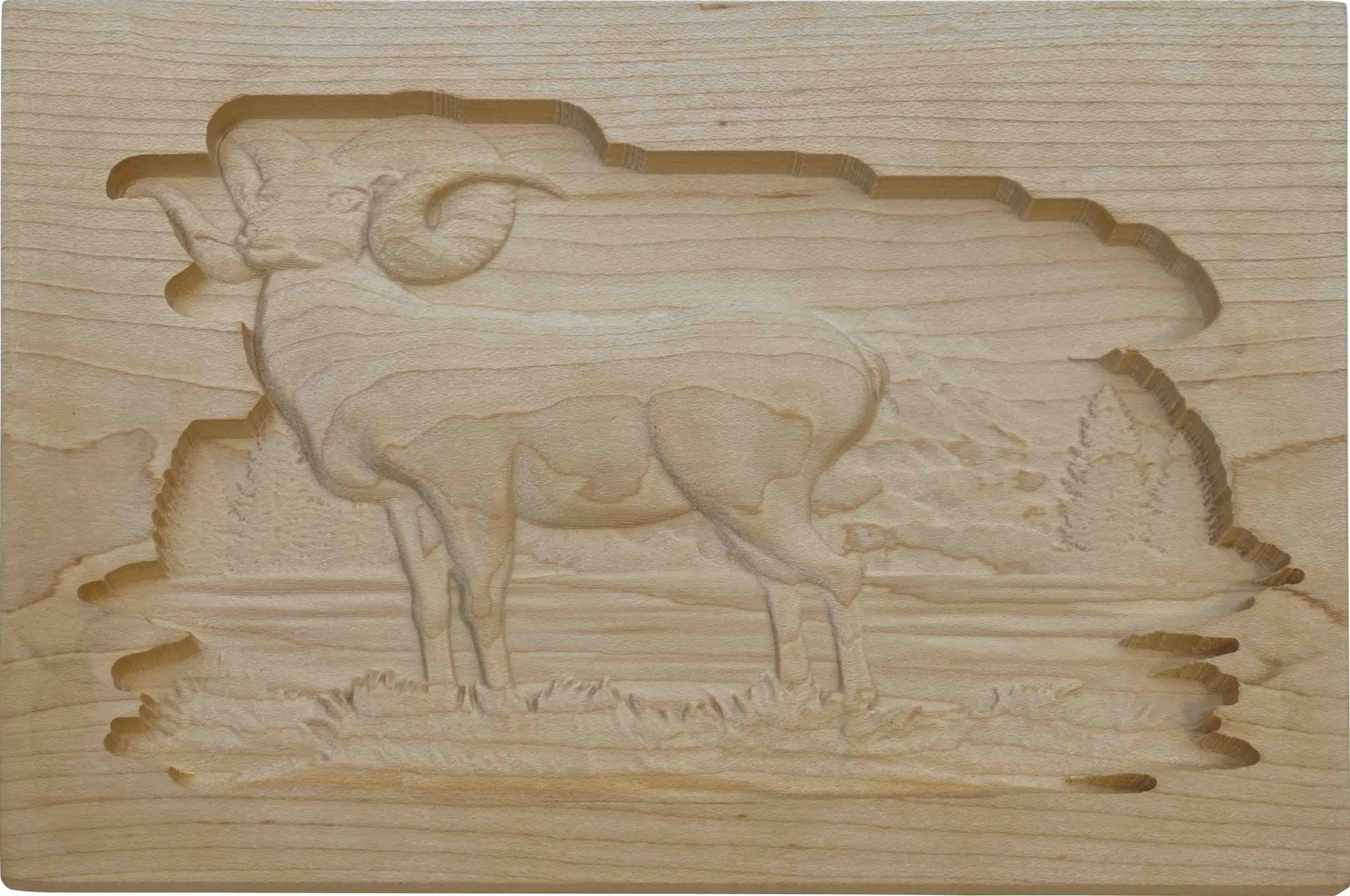

Even more complex objects can be made on a CNC router after diving into the world of ‘3D’ carving. Cuts like these are normally made by finding or making a 3D file, then processing that for the machine to cut. This is a slightly more involved process than using a drawing or picture. These “relief” cuts, as well as a few other examples of classic CNC router projects can be seen below.

Now that you know what a CNC router is and what it’s capable of, you should be able to get an idea of how you might use your own LongMill to make parts or projects in your home or for your business. The next pages should act to further deepen your knowledge on the primary concepts of CNC routing. We hope you also come to understand the process of how a project can be made on a machine like the LongMill.