The AltMill is compatible with the AutoZero Touch Plate!

Before we begin setup, please download the latest version of gSender.

Setup

Step 1: Unboxing

Each order for the AutoZero Touch Plate comes with:

- The AutoZero Touch Plate itself

- A cable that has a green connector on one end, as well as a magnet and banana plug on the other

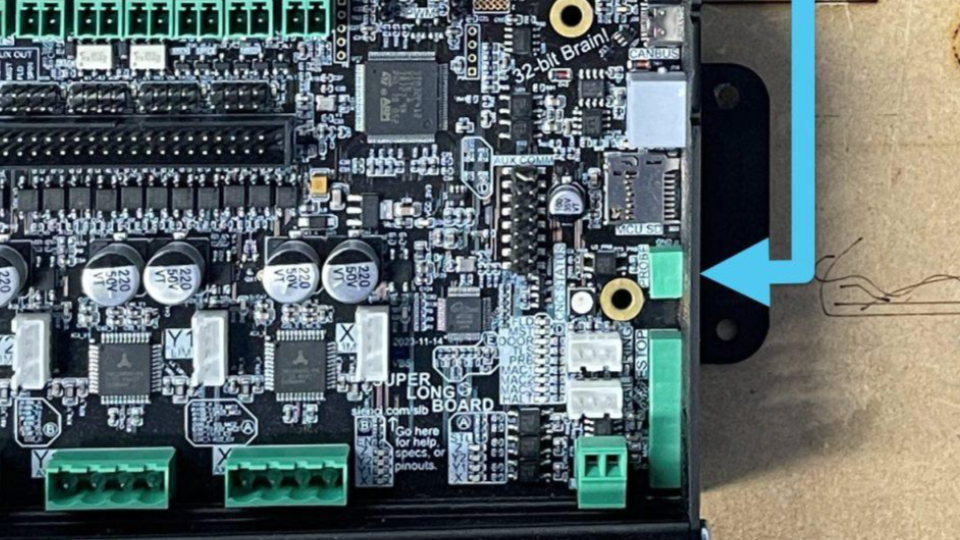

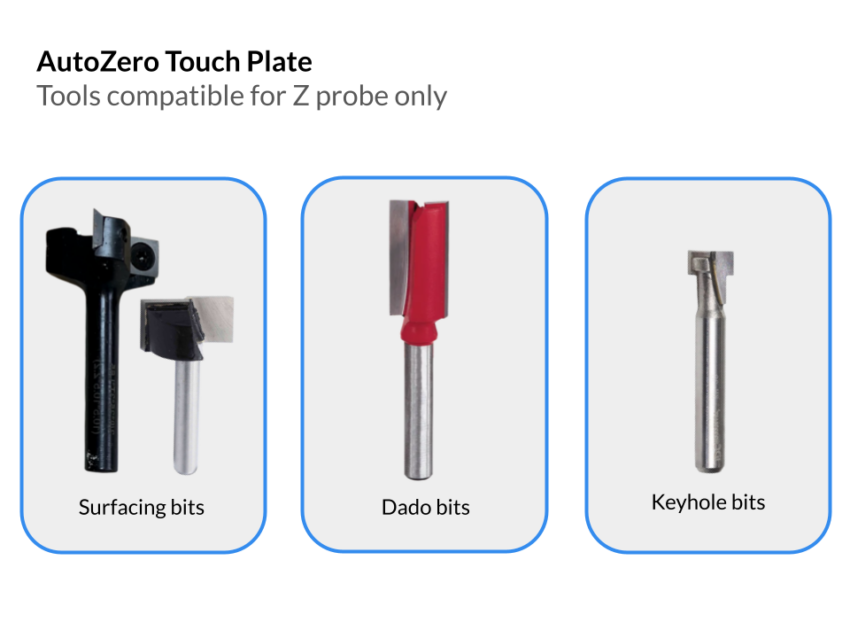

If your cable didn’t come with a green connector, you should find a spare one came with your board in a baggy or plugged into the board already (look for the writing “PRB” or “Probe”). These connectors are called 3.81mm pluggable screw terminals and can have wires attached to them using a regular, small flat head screwdriver. When you do this the wire order doesn’t matter.

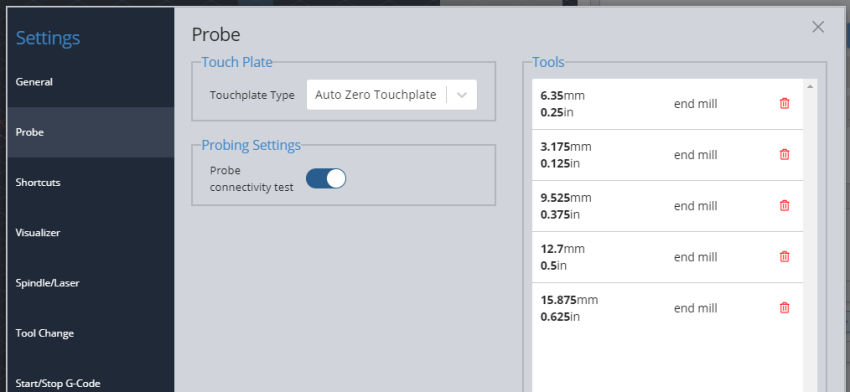

Step 2: Update your gSender settings

Step 3: Setting up the touch plate on your workpiece

The AutoZero can find the X, Y, and Z coordinates on rectangular pieces of material. The material should be square and flat to get the best reading. The AutoZero can also find the Z-height of most flat materials, regardless of their shape.

- Start off by plugging the green pluggable terminal into the controller. Make sure that it is in the PROBE/GND terminal.

- Plug the banana plug into the touch plate. There are two holes on the plate, either of which can be used to your preference.

- For probing in X, Y axes, put the block at the bottom left corner of your material. The inside edges should be touching against the sides of the material.

- If you are probing just the Z-axis, you can still place the probe on the corner of the material. Or you could flip it over and place it on the surface of the material; probing will happen on this back lip.

Step 4: Probing

Ensure that the magnet is connected to the router/spindle shank.

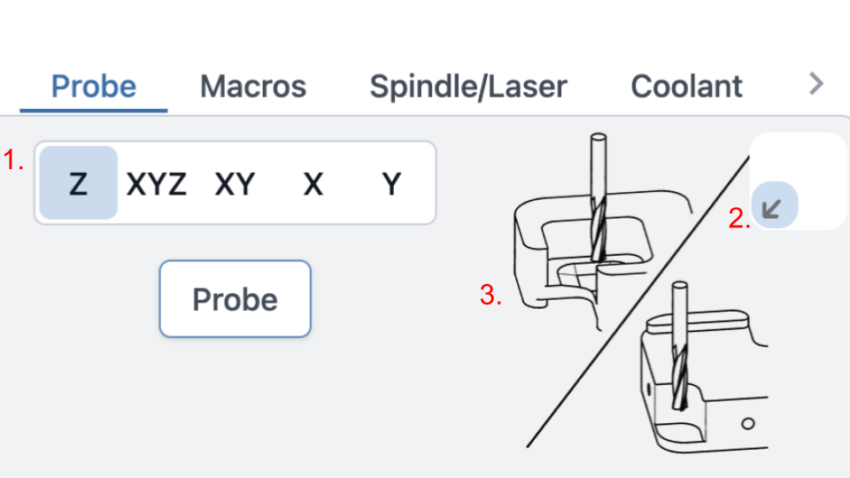

Select the axis you wish to probe in.

You may see the options “Auto” or “Tip.” Make sure you use the correct setting for your specific bit:

- Auto is used for straight end mills and bits

- Tip is used for v-bits, tapered bits, and ball nose

For the Z-axis probe, jog the bit above the back lip of the touch plate.

For all other probing (XYZ etc…), jog the bit over the inner square.

Then press Probe.

gSender will ask to check for the continuity of the plate before starting the process to ensure your probe has the proper connection. Move the touch plate to contact the bit.

Finally, once the circuit has been confirmed, start the probing process.

During the probing process, keep a hand against the plate to prevent it from sliding around. Be careful and make sure your hand isn’t in the way of the end mill.

Step 5: Remove magnet

Once your probing is complete, remove the magnet and move the touch plate out of the way. Your machine coordinates should now be updated and ready to use.

We hope you have an excellent experience with the AutoZero touch plate!

If you are running into any issues, make sure to check this video out below, as well as see our Troubleshooting section further down on this page.

Troubleshooting

Probing operation failed?

Here are some items to check:

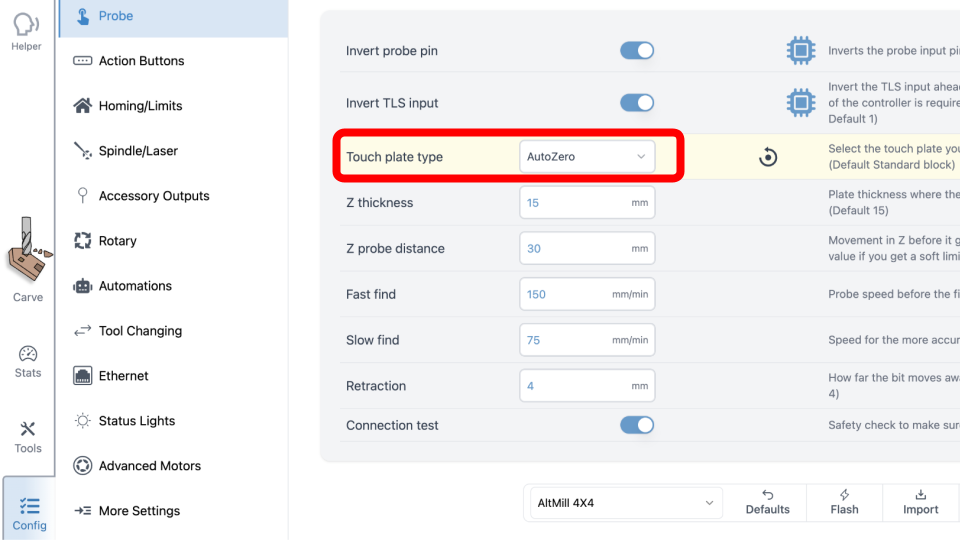

1. Make sure you have AutoZero selected in the touch plate type setting in Config

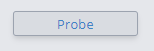

2. Some bits may be incompatible with the AutoZero, or may only work with the Z-probe.

- See the images at the product listing to check if your bit should work

3. If your tool is non-conductive, it would not work with the AutoZero

4. Make sure your work coordinates match your touch plate settings (usually G54)

5. Check the controller: first make a jumper connector by placing a wire into both ends of a spare connector. Insert the jumper connector into the controller. Open gSender, begin the probing operation. You should get the green go ahead to begin. If there is no change, the port on the controller might be the issue.

Using other Senders

Due to popular demand, we’ve created and tested macros to use the AutoZero touch plate with a variety of CNC control software beyond gSender.

If the software you use is not explicitly listed here, you can also follow instructions in the section titled “Macros for other senders” to use the AutoZero touch plate in a semi-automatic fashion as we work on expanding support.

Macros for CNCjs: Download for CNCjs

Macros for LinuxCNC/Buildbotics: Download for LinuxCNC/Buildbotics

Note: These macros were tested on the Buildbotics controller but they should also work with machines running LinuxCNC since they share identical variable / arithmetic formats.

Macros for Universal G-code Sender: Download for UGS

Note: The macros environment in UGS does not support arithmetic operations so probing with the X and/or Y axis using the AutoZero touch plate is a semi-automatic process. More specifically, you will need to click on the “Control Status (DRO)” panel and enter “/2” to halve the active coordinates in the X and/or Y after probing in these directions. If you have only probed either the X or the Y axis, you will only need to divide the coordinate of the axis which was probed.

Example dividing the X and Y axis coordinates after probing in UGS

Example dividing the X and Y axis coordinates after probing in UGS

Macros for other Senders: Download for other Senders

These macros will allow you to probe with the AutoZero touch plate using any CNC control software. Having said that, probing in the X and/or Y direction is a semi-automatic process in which you will need to manually halve the measure coordinate after probing.

To do so:

- Run the desired probing macro.

- If the macro involves probing in the X and/or Y axis (i.e. not probing Z alone), manually divide the coordinates you see after probing by 2.

- Enter the command G10 L20 P0 X[divided X coordinate] Y[divided Y coordinate] into the console substituting the coordinates in square brackets with ones manually calculated in step 2. If you have only probed either the X or the Y axis, you will only need to divide and substitute the coordinate for the axis which was probed.

- Home X and/or Y to check if the tool is at origin

Example dividing the X and Y axis coordinates after probing in any CNC control software

Example dividing the X and Y axis coordinates after probing in any CNC control software