There’s plenty more that CNC routers like the LongMill are capable of doing once you’re comfortable with the process of going from an idea on a piece of paper to a final product.

Project Ideas

If you’d like some inspiration, we spent some time putting together a categorized list below of all the items we could think of that can be made on a CNC router.

General

- Signs (house number, business, alert, etc.)

- Lettering (indoor decoration / kids names)

- Picture frames

- Wood boxes

- Stands, organizing trays, bins

- Clamping system

- Wood & wire inlays

- Automated CNC joinery

- Bow ties & inlays

- Stencils

- Engrave existing objects

Furniture

- Cabinetry

- Stools, step stools, poop stool

- Shelf / shelving unit / bookshelf

- Chairs

- Cradle / rocking chair

- Small bench

- Side tables / nightstands

- Laptop, tablet stands

- Monitor riser

- Coat rack

- Shoe rack

- Lamp

- Drawer pulls

- Tool storage / holders

Household

- Coasters / trivets

- Cutting boards

- Wooden plates, bowls, utensils

- Trays, charcuterie boards

- Cat / dog bowl stands

- Bottle opener

- Balance board

- Money bank

- Bookmarks / holders

- Candle holder

- Comb

- Toothbrush holder

- Shopping bag holder

- Glass rimmer

- Bookends

- Bird house

- Keychain

- Bathroom organizer

Toys & Activities

- Puzzles

- Mazes

- Chess Board

- Wooden sword

- Wooden cars / vehicles

- Board game

- Cribbage board

- Connect four

- Awards / trophies

- Elastic gun

- Wooden animals

- Dice holder / roller

- LongBoard

- Slingshot

- RC cars & planes

Art

- Sculpture

- Props, model making

- Custom guitar body

- Earring, necklace, pendant

- Badge

- Topography / mountain range

- Ocean / lake carving

- 3D face

- Custom mask

- Custom stamp

- Branding iron

Other

- Injection mold dies

- Carbon fibre frames

- Circuit boards

- Lost foam / wax casting

- Gears

- Custom ruler

- Coins

CNC Creator Guides

If you are looking for cool projects to create, then you are at the right place. We are creating individual e-books for awesome projects that we make YouTube video tutorials on called CNC Creator Guides. These guides are perfect for beginners interested in learning how to create projects on their CNC. They consist of downloadable project files and contain detailed step-by-step instructions with images, making it easier for the maker to understand and follow along. By following these guides, you can successfully build these projects and show off all your hard work.

Creator Guide List (to be continued)

Online CNC File Sites

If you’re looking for some more inspiration, or would like to start by making some pre-made projects, there are plenty of places online which offer pre-made artwork, drawings, and 3D models that are either free or can be purchased. In order to start you off, we put a list of some of these places together. Please note that we’ve done our best to filter out reliable file sources, but downloading any files online can pose a risk so be sure to only get files from sources that you trust.

Art / Drawings

- Sienci Labs Projects Repository (our Google Drive storing projects we featured on YouTube)

- Obrary

- Maslow Community Garden

- FreePatternsArea (templates)

- FreePatternsArea (projects)

- Ameede (need to wait 45 seconds for download)

- FreeDXF (sign-up rqd, free & paid content)

- 3axis.co (need to wait 5 seconds for download)

- CNC Cookbook (free dxf files)

- ToolsToday Pattern Directory (links to free and paid content)

- Scan2CAD (free collection every month, sign-up rqd)

- ZenziWerken (2D and 3D files, all free, made by one guy: Daniel)

- CutRocket (good project details, files only for Carbide Create, sign-up rqd)

- Inventables Projects (can only open projects in Easel, sign-up rqd)

- ShaperHub (can only open files in Shaper Website, sign-up rqd)

- Ready To Cut (projects from the community, sign-up rqd)

- AKER (source files) (garden products, need to “pay” $0 for files)

- wikiblock (most content is paid)

- modifile (parametric furniture, sign-up rqd, all content is paid)

- DesignShop (paid membership rqd, most models paid in addition)

- Ariba Box (sign-up rqd, free & paid content)

- Etsy (CNC patterns) (sign-up rqd, all paid content)

- CNC Router Design (sign-up rqd, all paid content)

- Buildbotics Projects (old, almost empty, broken images)

- cnc4free.org (non-commercial use)

- AtFAB (furniture, sign-up rqd)

- https://www.opendesk.cc/designs (furniture)

General sources:

- My DXF

- Love SVG

- PNG Repo

- SVG Repo

- PlotterFiles

- flaticon (icons & icon packs, sign-up rqd, free & paid)

- Pixabay (must check captcha for download unless logged in)

- VHV.RS (non-commercial use)

- Clipart Library (non-commercial use)

- Some of the 2D file making programs also come with a small subset of free 2D files

3D Models

- Sienci Labs Projects Repository (our Google Drive storing projects we featured on YouTube)

- Sienci Labs’ Thingiverse collection (our curated list)

- Cults 3D (reliefs)

- Thingiverse (CNC projects)

- Design & Make (good models, sign-up rqd, most content is paid)

- VectorClip3D (sign-up rqd, most content is paid)

- 3D Wave (sign-up rqd, all content is paid)

General sources:

- Thingiverse (nice community, good selection)

- MyMiniFactory (nice community, most models free)

- Free3D (cool models, some content is paid)

- YouMagine

- Clara.io (medium-sized database, sign-up rqd)

- 3DContentCentral (large database, sign-up rqd)

- GrabCAD (large database, sign-up rqd)

- Cults3D (sign-up rqd, lots of paid content)

- pinshape (nice community, sign-up rqd, some content is paid)

- Thangs

- PARTcloud (assorted models)

- Open3DModel

- Libre3D

- Repables

- TouchTerrain (topography generator, limited abilities)

- Terrain2STL (topography generator, limited abilities)

- The Terrainator (topography generator, sign-up rqd, paid)

- NASA (3D resources) (NASA models)

- embodi3D (medical models, sign-up rqd, some content is paid)

- AfricanFossils.org (models of African fossils, sign-up rqd)

- zortrax (small collection, sign-up rqd)

- 3D CAD Browser (sign-up rqd, odd system of requiring uploads to download, free & paid models)

- yeggi (search engine for 3D printable models)

More Sample Projects

There are a few more internally designed projects that you can also try out if you wish. Each project has a download which contains both the g-code files made for each specific project (pictured) and the original 3D files if you want to CAM them yourself. There are even more designs that we’ve made for use on the LongMill that can be found here if you’re interested in giving them a shot: LongMill Demo Pieces

Wooden Box

A great starting project for the woodworker at heart. The hardness of wood varies by species and other factors, however most commonly available woods such as pine, oak, cedar, maple, or cherry are quite easy to work with. A depth of cut of about 2mm at around 700mm/min works well with soft to medium hardness woods, but you should reduce the depth of cut to around 1mm if you’re working with a very hard wood. Medium speed on the router at around 20,000RPM works well.

The following box was designed by Andy. It’s beautiful in its simplicity and fits together nicely. Refer to our Feeds and Speeds table to set up your machine based on your choice of wood.

Material: Any species of wood you wish, at least 22mm tall for the base and 13mm tall for the lid

End Mill: 2-flute, 1/4″ end mill

Cutting Time: 25 minutes

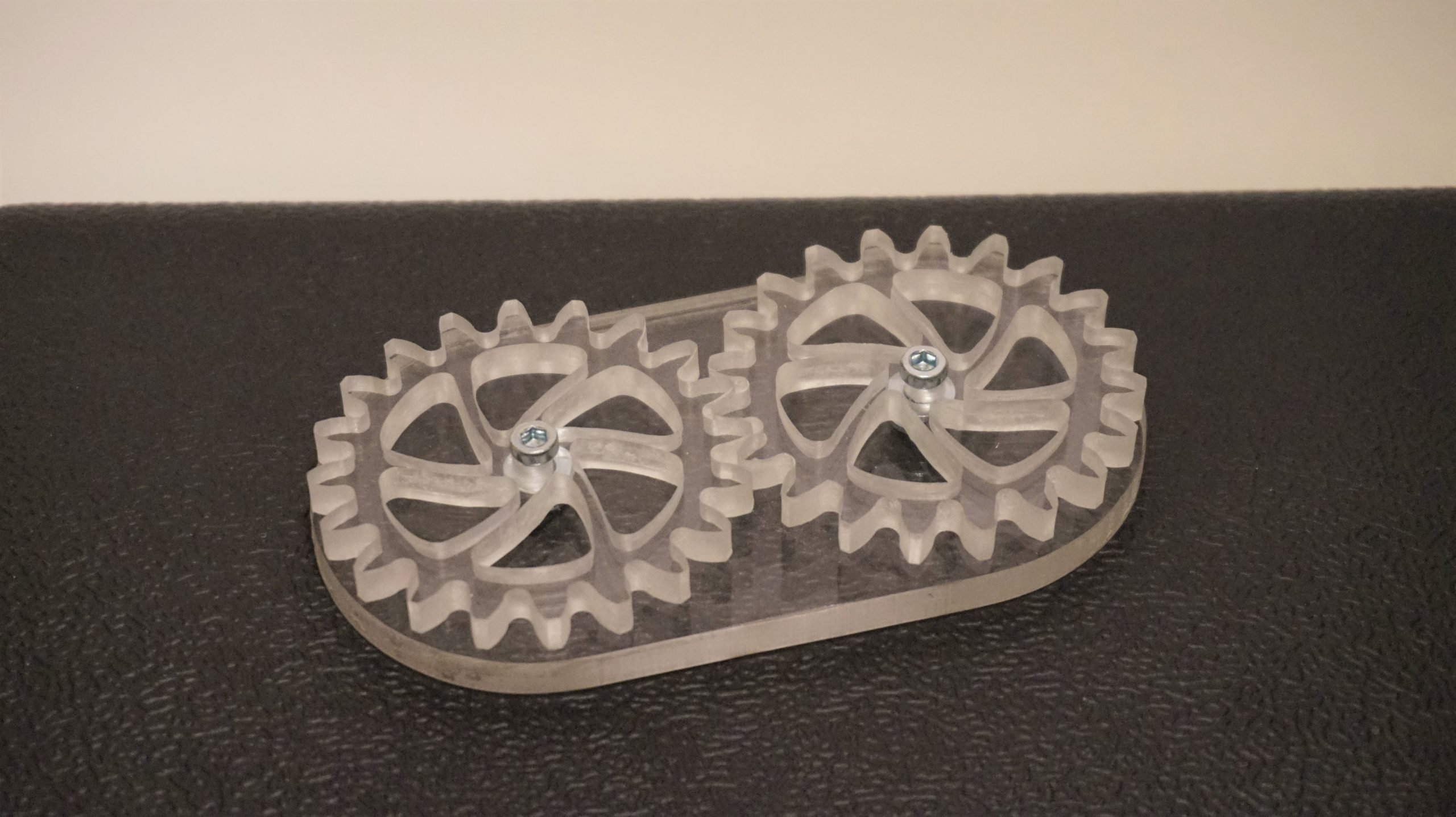

Acrylic Gear Train

Acrylic is a sturdy and useful plastic, commonly used in robotics applications due to its functionality, availability, and looks. At the right speed, acrylic and other soft plastics can be smoothly milled to yield very beautiful results. Generally, you’ll want to aim for an 800mm/min feed rate at a 1.8mm depth of cut. You’ll notice that there are burrs and debris left behind on the cut surfaces if the right speeds and feeds are not selected. Choose spindle speed around 24,000 RPM and adjust these settings as you need to get the best results.

This gear train was designed from scratch by Chris. If cut properly, minimal drilling should be required to use two M4 bolts and washers (or 8-32) and thread them into the gear train base.

Material: 6mm acrylic

End Mill: 2-flute, 1/8″ end mill

Cutting Time: 14 minutes

Aluminum Bottle Opener

A start at using the hardest material in the Mill One’s capability range. Aluminum comes in a variety of alloys, but the most common is 6061 Aluminum. It’s a fairly hard and strong material and can be found in aerospace components and bikes. The trickiest part of milling aluminum is preventing the aluminum chips from melting and binding to the end mill, which will stop the end mill from cutting. In order to carry the right amount of heat away via the chips, we recommend an 800mm/min feed rate at a 0.4mm depth of cut and 0.2 step over. The depth of cut is also slower, about 100mm/min.

Choosing the right spindle speed for milling aluminum is a highly debated topic for hobby CNCers. Traditional machines set their spindle speeds at around a few thousand RPM, however routers like the ones used on the Mill One run between 10,000RPM to 30,000RPM. To get around this, less flutes are used (one or two) with shallower cuts and faster feed rates.

Both of these fully functional bottle openers were designed by Chris. They have a sleek, industrial feel and are certainly conversation starters in any scenario.

Material: 1/4″ and 2.15mm 6061 aluminum

End Mill: 1-flute, 1/8″ or 3mm end mill

Cutting Time: 12 minutes and 2 minutes