Spindle and Controller Connections

The instructions below must be followed in the exact order they are presented, otherwise the controller won’t be able to communicate with the VFD and will present an ‘Alarm 14’ error.

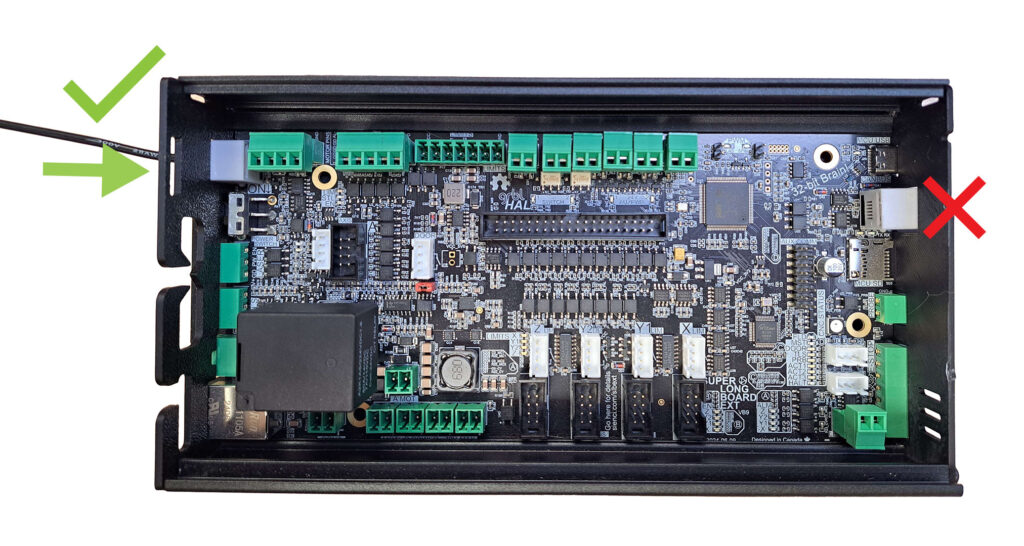

If your SLB-EXT is powered on, please turn it OFF now.

Power switch on SLB-EXT

Ensure that the spindle cable connector is installed on top of the spindle.

Connecting spindle cable to spindle

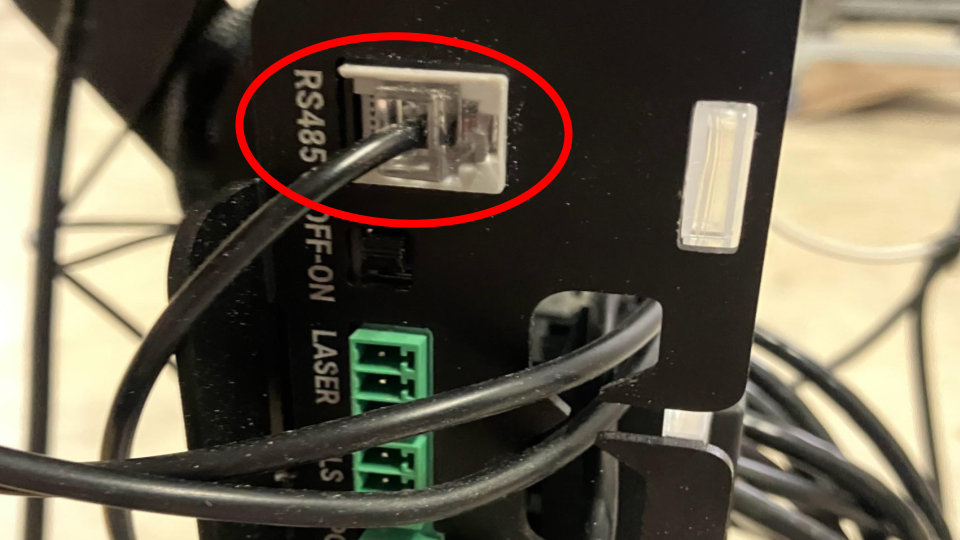

Then check that the RS485 wire is plugged into the SLB-EXT controller.

Connecting RS485 to SLB-EXT

Ensure the RS485 cable is plugged into the connector above the OFF-ON switch and not the connector below the USB cable.

RS485 Correct Connector Location

Plug in the power cord from the VFD unit into a wall outlet or extension cord now. If you’re using an extension cord, ensure that it is rated for 1500W of power. The VFD must be ON before the SLB-EXT, otherwise they will not properly “greet” each other.

Connecting spindle to power

The VFD screen should blink on with red text. Blinking text is normal behaviour for the VFD display.

Turn ON the controller using the power switch and make sure the E-stop is released. We will now move to setting things up on gSender.

Connect to gSender, as you did in the First Movements section.

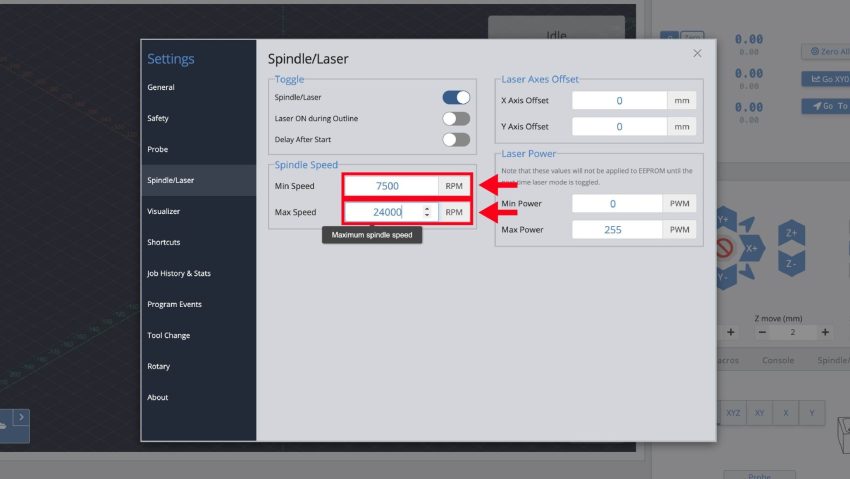

gSender Settings

Open the dropdown menus below to see the correct setup steps for the gSender version you have.

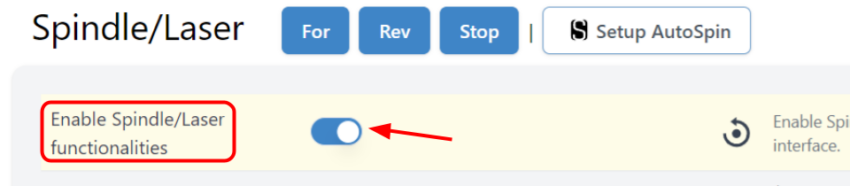

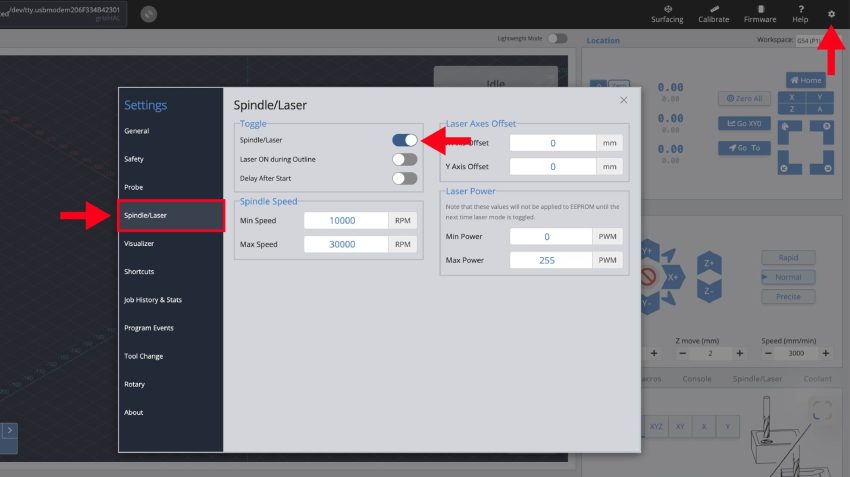

gSender 1.5.0 and above

gSender 1.4.12 and below

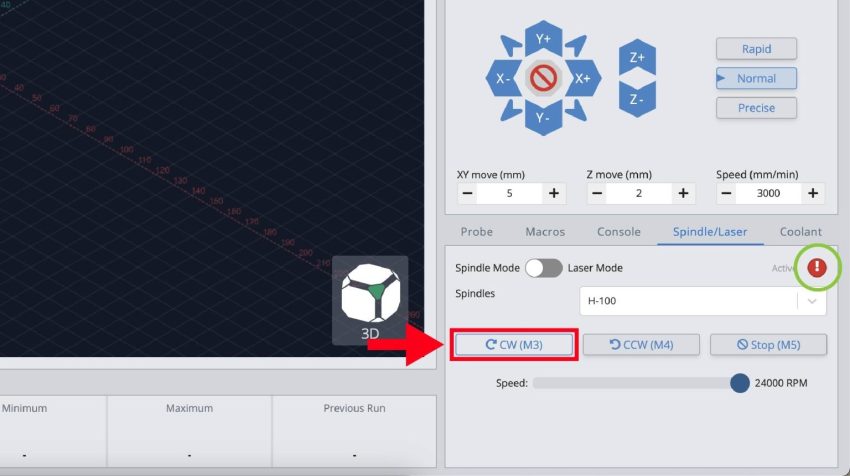

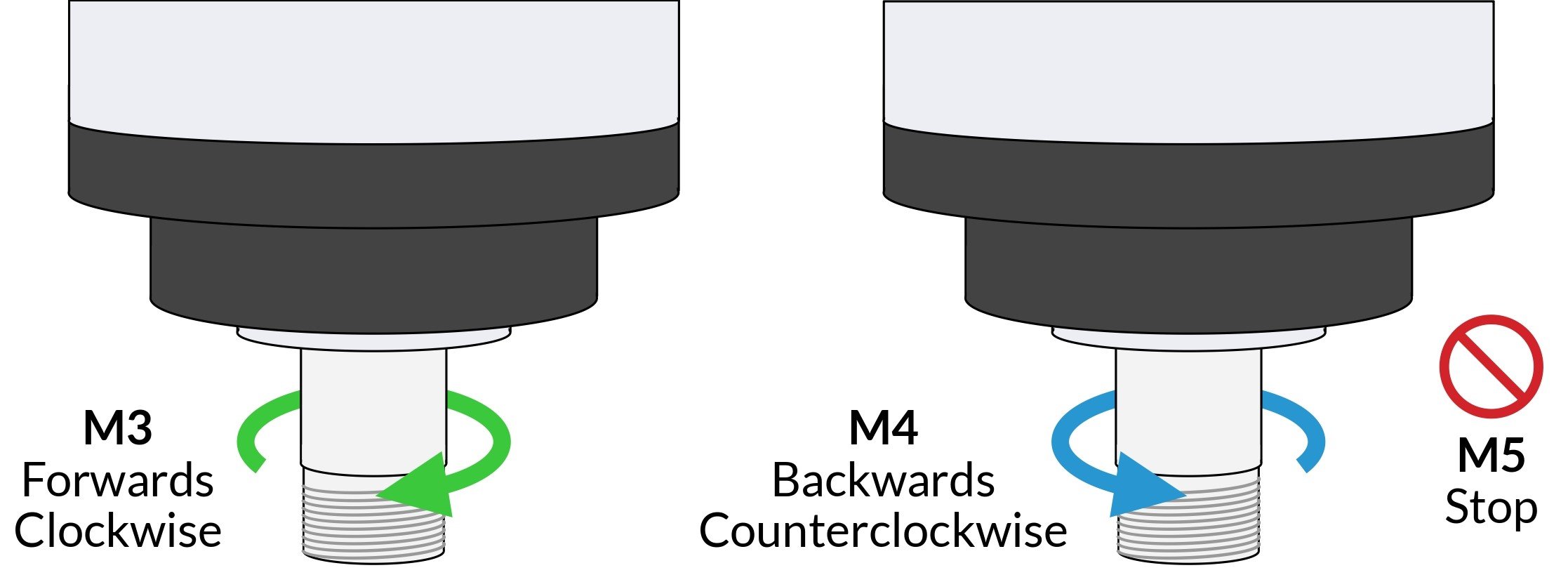

Spindle Direction

While testing, make sure the spindle is spinning the correct direction by watching as the spindle slows down to a stop once done.

Direction of spindle

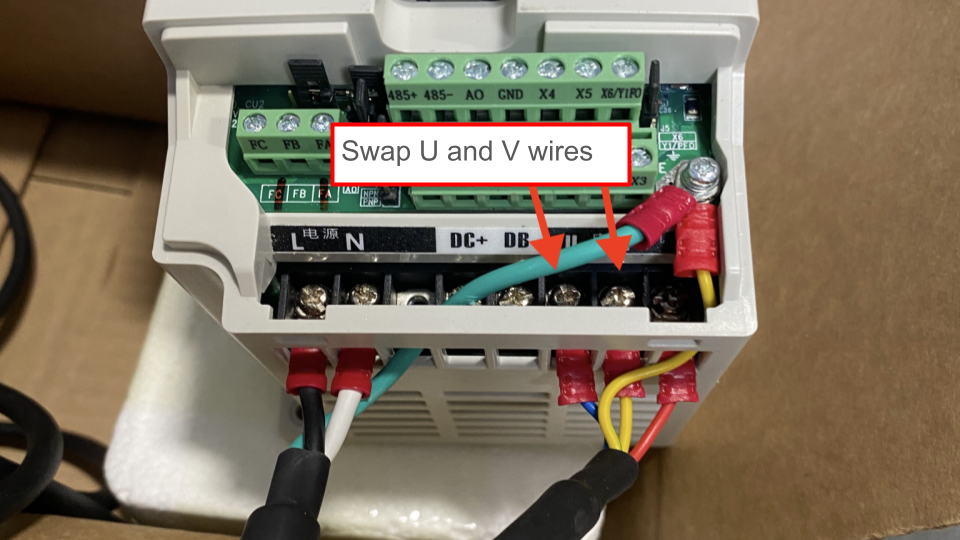

If the spindle is spinning in the opposite direction, swap any of two wires on the U, V, W terminals. Warning, Electrical Hazard! Unplug the VFD from the power source and the controller before swapping the wires.

Changing spindle direction using U, V wires

Spindle Break-in

The grease inside the bearings may have shifted during transportation, it is recommended that you run a “break-in” cycle to redistribute the grease before using your spindle. To do this, you can download and run the g-code file below on gSender, which should take 1 hour 40 minutes to run.

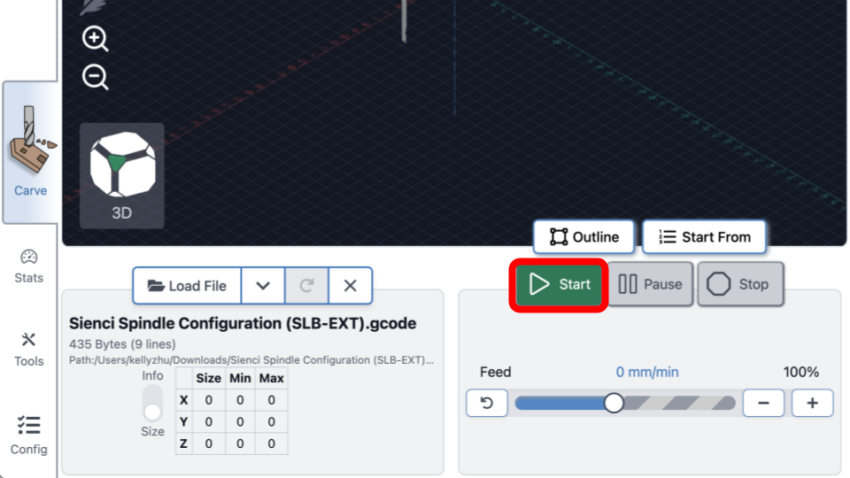

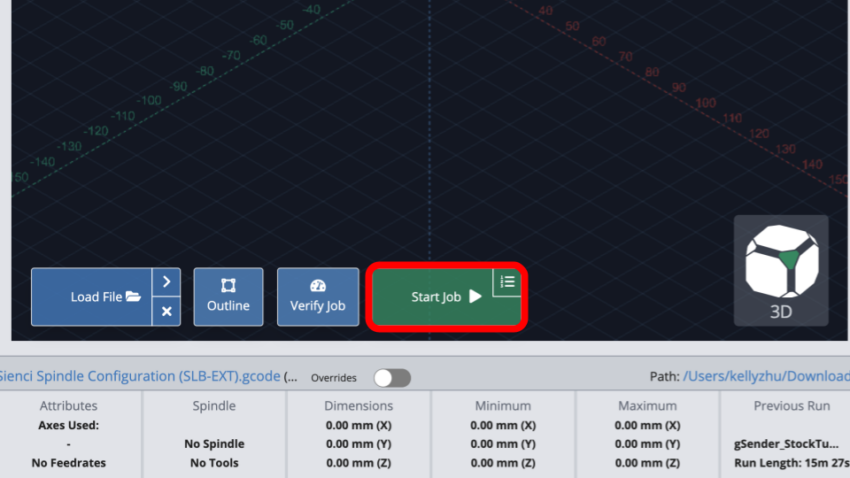

To run the file connect to gSender and press ‘Load File’ at the bottom left corner. Select the file and you should see a ‘Start Job’ button appear, go ahead and click that.

Finishing Up

Congratulations on completing spindle setup! This is one of the trickiest parts of getting the AltMill ready.

If you are done for the day, just turn off the SLB-EXT controller using the power toggle. You can leave the VFD plugged into wall power.

However, if you choose to unplug the VFD, please follow this precise order for starting up each time, to avoid alarms:

1. Make sure the controller is plugged into power but turned OFF

2. Plug spindle into power, the VFD should blink with red text

3. Then turn on the controller using the power toggle

If you have already set up your wasteboard, feel free to continue into the Final Checks article. Otherwise, to the Wasteboard we go!