The AltMill project, being of slightly more in the ‘Prosumer’ category of CNC routers, means that it is less feasibly replicable for anyone looking to build their own. Nevertheless, we believe that making the AltMill project open-source is highly beneficial to both existing owners, and anyone interested in the project as a whole.

The idea is for:

- Users to modify and improve their machines to fit their needs

- Machine owners to share their designs with the community to help others that have similar needs

- Makers to use our design ideas and design philosophy to create other types of machines, such as laser cutters, plasma cutters, and 3D printers

- Us to gain inspiration from the community to help us guide our development of current and future products and features

License

This is accomplished by putting the project under a Creative Commons BY-SA license:

- The entire mechanical design of our AltMill CNC available in a range of 3D file types and as drawings where applicable

- Any internal assembly jigs and other supporting hardware for the AltMill

- All educational information provided within the AltMill Resources area including machine assembly instructions and modifications

- Every aspect of the electrical design behind our custom SLB-Ext CNC controller including BOM, schematics, gerber file, etc

All this information is continually updated as the AltMill project continues to be revised, with more openly shared information being made available at each new major revision and licensing continuing to be applied to all previous major versions. By making this information available, the AltMill project fulfills the Open Source Hardware Association’s definition of open source hardware.

AltMill Onshape CAD Document

The design of the AltMill MK1 and MK2 mechanical assemblies can be found here:

AltMill MK2: https://cad.onshape.com/documents/e6c1dae7dec3a7538aec8593/w/b499e6bd64fb86ce75f092e0/e/0c453dfc59663a58da0a872a

AltMill MK1: https://cad.onshape.com/documents/800a50dcf74a5da8494df761/w/a0738e17b55d9464f0929cef/e/7ab3cbf10651caebb09b6ff9

The above link points to our 3D CAD model of the AltMill which is hosted on a website/platform known as “Onshape”. This is the browser-based software that the engineers and designers on our team use to design and iterate on all the products we produce at Sienci Labs. The fact that it’s online has the great advantage that anytime we make an update or release a new product, you are able to see them live or download them for yourself. We feel this is a great way to keep our company open and make our designs easily accessible to others.

If you want to Export our Onshape designs as either a 3D model (STL, IGES, STEP) or a 2D drawing (DWG, DXF) for your own tweaks or accessories:

- Open the link to the design you’d like to download.

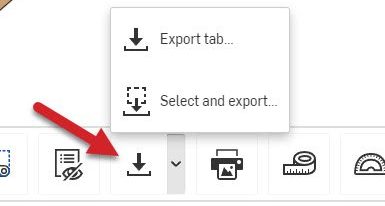

- Use the ‘Export’ option in the toolbar to either export the whole design or use the down arrow to allow you to export only individual parts or assemblies. You can select these parts by clicking on the 3D model or by clicking on the parts list on the left-hand side of the window. You can also select individual faces of parts or surfaces to export these as DWG or DXF files.

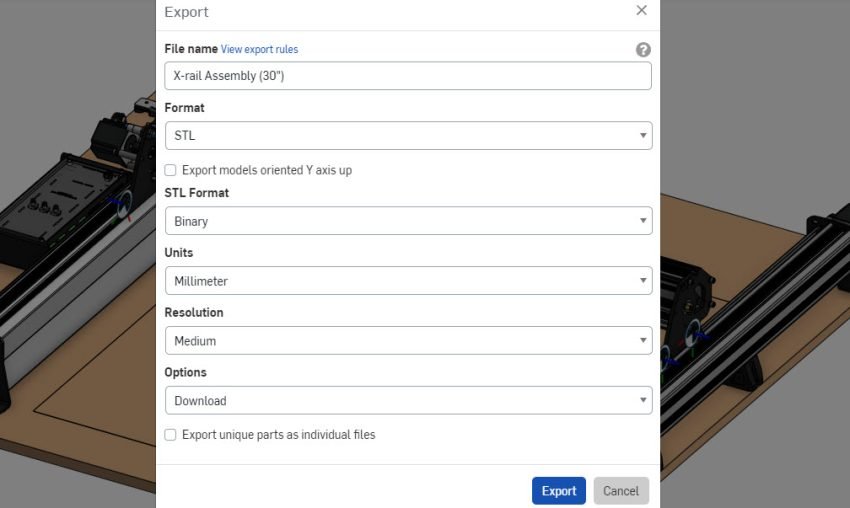

- When you’ve selected all your parts, you’ll be given more options to choose the file type you want to download as and other options based on your selections. Typically STLs are used for 3D printing, IGES and STEP are good for importing to other design software to modify the files, and DXF or DWG are used for laser or plasma cutting. Typically the other files defaults tend to be good to use.

SLB-Ext Controller

The SLB-Ext controller used with the AltMill CNC router is a variant of our latest ‘SuperLongBoard’ controller. This controller has a few unique features from the regular SLB controller that make it more suitable for larger, heavy duty CNC routers such as the AltMIll:

- Step and direction outputs with differential signals and buffering for robust control of up to 5 external motor drivers

- Motor alarm inputs

- Motor power distribution to up to 5 external motor drivers

- Latching emergency stop circuit, overcurrent protection, and relay wear protection for safety

- Power electronics compatibility for up to 80VDC systems

You can read more about the SuperLongBoard controller, which shares all other core functionality with the SLB-Ext controller here.

80mm Dust Shoe

If you would like to print your own 80mm dust shoe as a replacement or for your 3rd party spindle, the files can be downloaded here.

80mm Dust Shoe Print Settings:

All print files are scaled and oriented appropriately as is in millimetres for your respective slicer.

Print using a 4mm nozzle with 0.2mm or finer layer height. Default settings for your slicer should suffice unless otherwise stated. Increasing flow rate tends to help with part strength and quality on lower output extruders.

For the Spindle Body it is recommended to use tree supports (if available in your slicing software) around the large overhang towards the back of the part and around the window cutout – try to avoid leaving remnants of supports on the groove where the window is seated.

All other parts should not require supports for printers where they can successfully print up to a 28 degree overhang angle and with good bridging settings. If supports are required, it is recommended to use tree supports and avoid areas where parts interface with one another.

Stepper Motor Covers

If you are looking for the AltMill MK2 motor covers, you can download the STL file here: CLSMotorCover. You will need M3-45mm socket head cap screws to fasten them onto the motors.