So you just purchased your AltMill…now what? While you’re waiting for your machine to show up, you can:

- Familiarize yourself with fundamental CNC concepts and workflows

- Buy a sheet of 4’x8’x¾” MDF for your table, and think of how you would hold down your projects during cutting (aka workholding)

- Source your spindle if you are not getting it from our store

- Install the proper electrical, if using a 220v spindle

- Grab cutting tools for the types of projects you’re interested in making

- Figure out your dust collection system

- Determine what computer you would need, if you are not getting gControl panel

- Familiarize yourself with the software options available, and set up your post processor

- Clear a work space in your shop or garage for the machine

- Join our Facebook group and Forum for community-driven discussion and inspiration!

Workholding

The AltMill comes with a sturdy frame that you can mount a table surface and wasteboard to. The ¾” thick 4’x8’ MDF sheet (purchased separately) will act as our table surface and will attach onto the frame with screws. Full instructions can be found here. The wasteboard is mounted on top of the table surface, and can be fully customized to suit your application, allowing for various workholding options to be implemented. Here are some common examples of workholding methods used in consumer-level CNCing:

Using clamps

- T- tracks with MDF slats

- Grid of 5/16” threaded inserts, counterbored on a second MDF sheet

Using adhesives

- Painter’s tape with CA (cyanoacrylate) glue, on a second MDF sheet

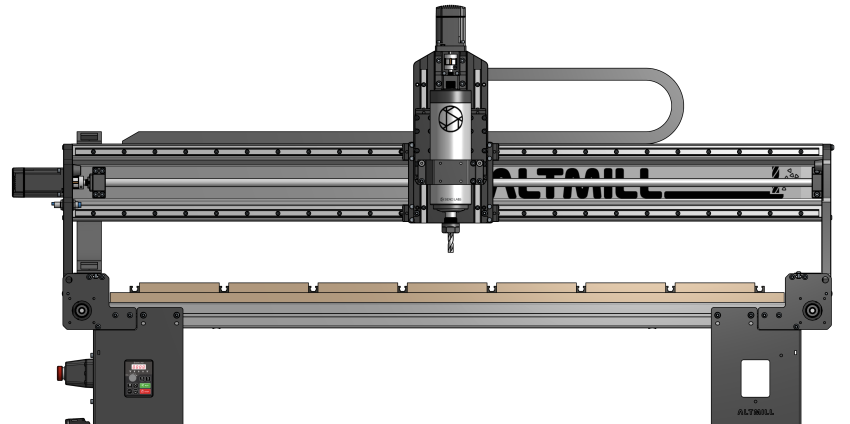

Front view of AltMill with MDF table, T-tracks and MDF slats

Spindle

For the AltMill, we recommend using our Spindle Kit since it is already pre-programmed and tested under our specifications. It is air-cooled and rated at either 1.5KW or 2.2KW.

However if you are looking for another option please keep in mind:

- For spindles 2.2KW or above, you will need to install extra 220VAC wiring

- The AltMill comes with an 80mm spindle mount, we do not have larger diameter mounts at the moment

- The VFDs that may work with our controller are: Huanyang v1, Huanyang P2A, Yalang YL620, H-100, and GS20

- Third-party spindles are NOT plug and play, and we have limited technical support for them, please read this article for further information

AltMill 1.5KW 110V spindle

Cutting Tools

There is a vast variety of end mills and specialized bits available for different use cases, from carving signage to cabinetry pieces. The video below explains the basic features of a cutting tool, and highlights the differences between common types of tools.

Further reading on the recommended tools for specific project types can be found here.

Dust Collection

Having proper dust collection for you CNC machine will:

- Keep dust out of the air and on sensitive machine components

- Remove chips and debris out of the cutting areas, reducing the chance of rubbing or burning

- Reduce cleanup after your job is completed

The general specifications for a dust collector suitable for the AltMill are as follows:

- 1-3hp

- Single, double or triple bag

- 4” diameter hose (or you can source/make your own adapter)

- At least 600 CFM rated flow rate

Also known as the vacuum attachment, the dust shoe is connected to a hose leading to the dust collector, sucking up debris on the work surface. If you are choosing a different dust shoe for the machine, here are some factors to consider:

- Spindle size

- Hose size/suction power

- Z-axis adjustability of the dust shoe

AltMill 4″ Dust Shoe

Work Space

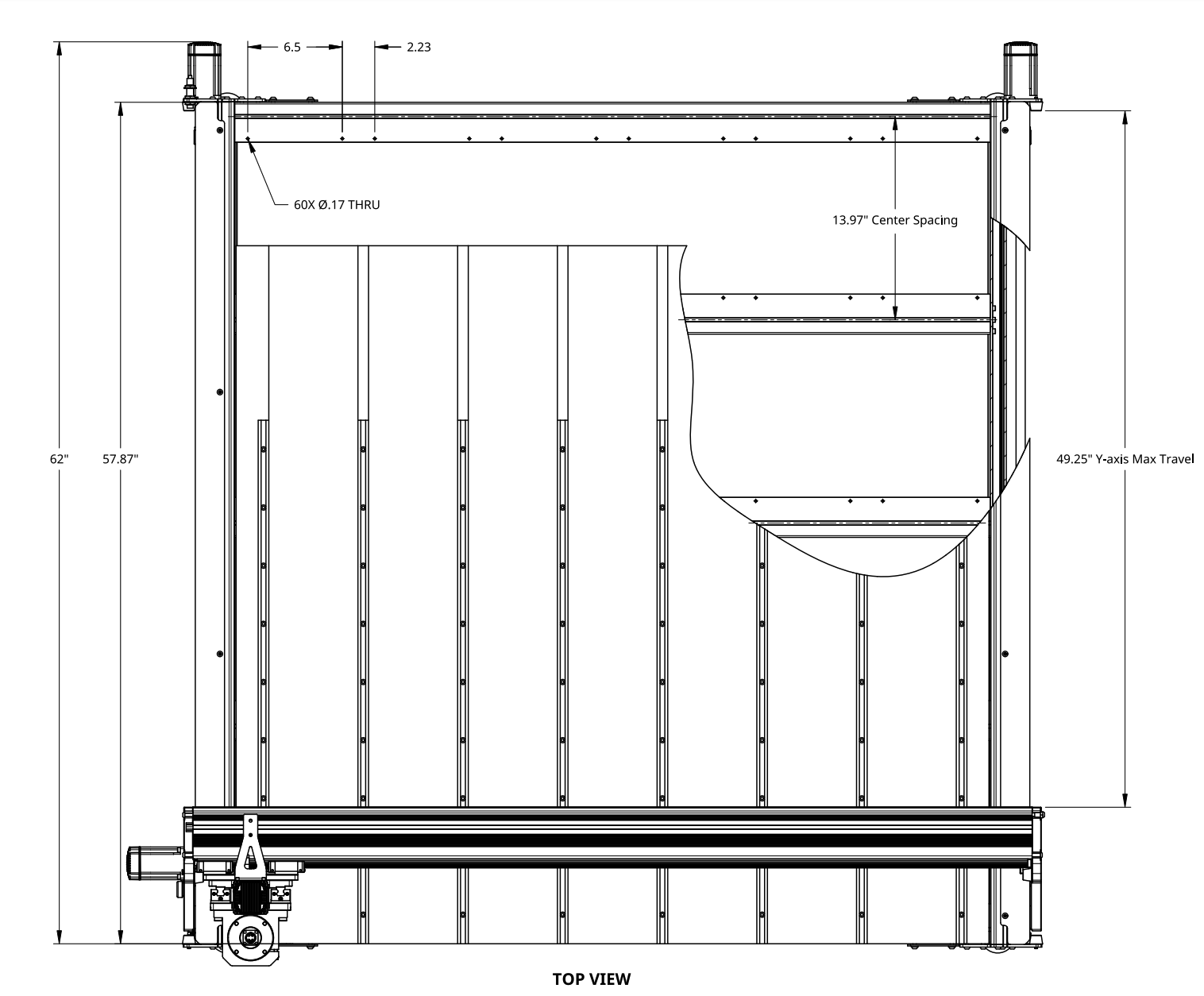

Detailed drawings for the 2×4 and 4×4 AltMill can be found on this page. Ensure that you allocate at least 6’x12’ of space for the machine build.

Top view of AltMill MK1 4×4 showing width and depth dimensions, PDF found here