Most hobby CNC routers will utilize an off-the-shelf trim router, such as the Makita RT0701C. Although these are suitable for hobby use, they have some limitations both in regards to reliability over long periods of time, and a lack of ability to automate their control. Trim routers offer a more ‘analog’ experience, where users must manually set the router speed using a physical dial, and turn on/off the router at the start and end of a cutting program. Despite all this, trim routers have a proven track record of being a very capable, easy to install option for relatively little cost.

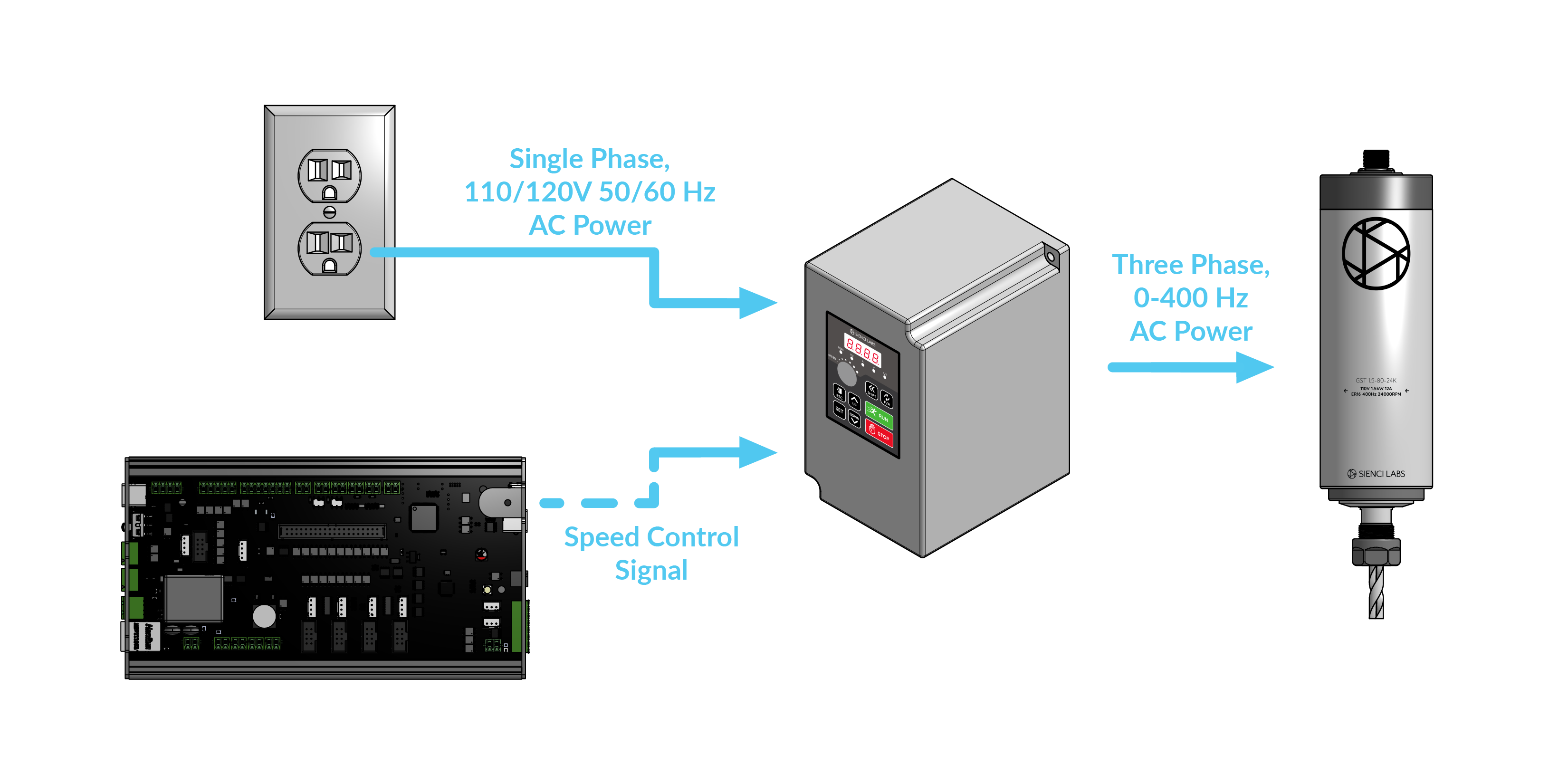

A key difference between routers and spindles is that a router houses all of its electronics inside of itself and plugs into a wall outlet directly, but a high speed spindle contains only the motor and rotating elements, while an intermediate ‘VFD’ (variable frequency drive) unit is used to direct power from the wall outlet to the spindle motor like shown in the diagram below.

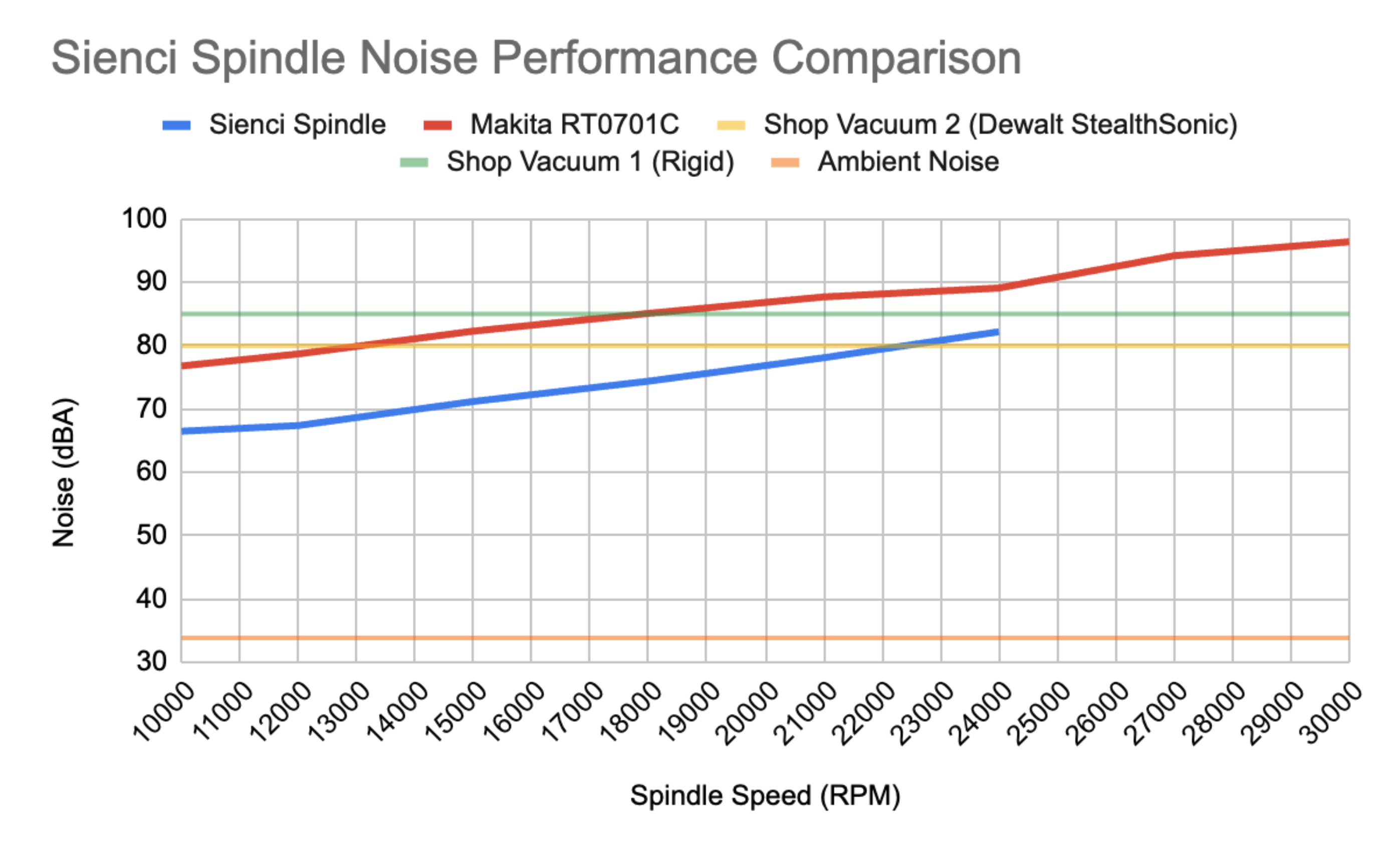

Spindles are designed to be more mechanically robust than trim routers, in order to withstand long cycles of cutting. The addition of the VFD unit allows for advanced spindle control capability, which can be set up for a given CNC application. Furthermore, since spindles are brushless, they generate much less noise than routers, and do not wear down any motor brushes that could require replacement. To hear the difference between the two, we’ve also created a short video demonstration comparing the two at various running speeds.

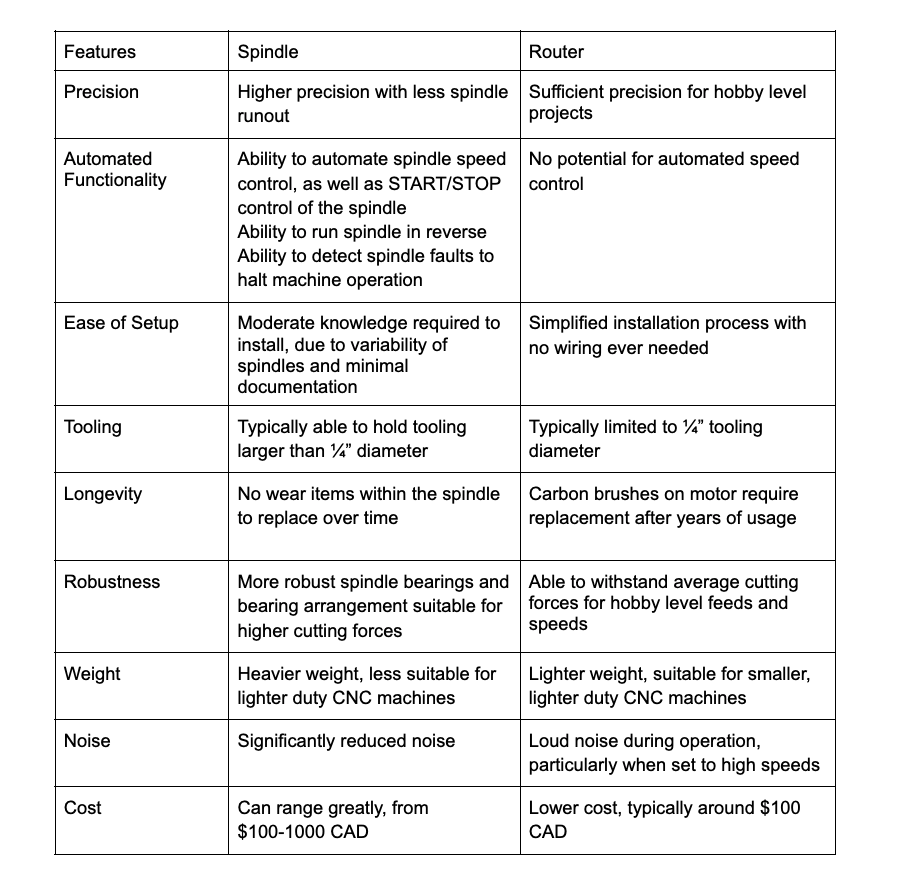

Below we have compiled a summarized chart comparing spindles and routers, assessing various features and criteria.