Machine is not powering on

Usually this means the E-stop is latched, so you need to power cycle each time to turn on the machine. If the machine is temporarily turning on and then shutting down, unplug the power and let it cool down for a minute, then re-plug the power and power cycle again. If none of these work, unplug all motor power connections from the controller, then power cycle again.

Motors

Incorrect motor behaviour (direction, speed, distance)

This could be related to firmware settings, electrical or mechanical setup.

1. Please try to either power cycle the board or reset it back to the firmware defaults by sending the “$RST=$” command. If these methods do not work, check that the settings in the ‘Firmware’ tool match these as shown in this PDF: altmill-default-settings-for-motors as they affect motor direction, holding, steps/mm, speed, acceleration, and more. The most important settings are $3, $100, $101, $102.

2. Check that the DIP switches on each motor are in the proper positions, as shown in the photos below. Please note that X and Y motors will be set differently from Z.

Correct motor DIP switches setting for X and Y-axis, from 1-5: OFF OFF OFF ON ON

Correct motor DIP switches setting for Z-axis, from 1-5: OFF OFF ON ON ON

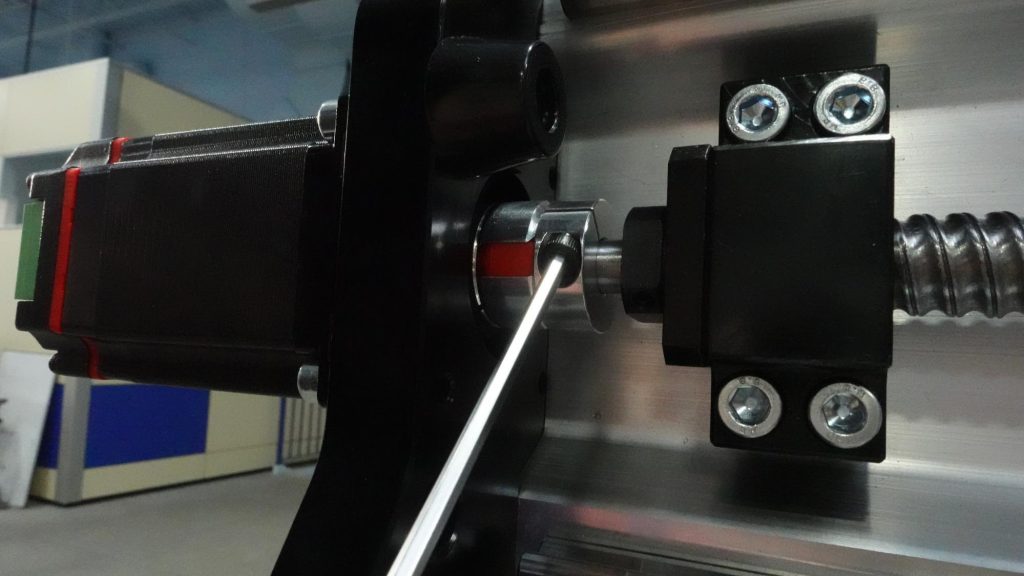

3. Make sure that the couplers are tightly fastened onto the ball screws and motor shafts.

Tightening coupler using Allen key

Z-axis stops moving midway through job

Z-axis motors may be thrown into a position tracking error due to the combination of high microstepping and acceleration settings. In this case, changing the microstepping values used by the Z-axis motor can prevent this issue. First, turn off power to your machine. On the back of the Z-axis motor, you’ll see a set of five DIP switches, each numbered. Flip the DIP switch labelled as ‘3’ to the position of ‘ON’ (this may be set to ‘OFF’ by default). Then, turn machine power back on. Next, go into the firmware settings for the controller within gSender, and scroll down to find the value ‘$102’ used for Z-axis travel resolution. Change this to a value of 200, then click ‘Apply new settings.’

Machine is not moving at all

This could be attributed to motor-related firmware settings and/or electrical connections.

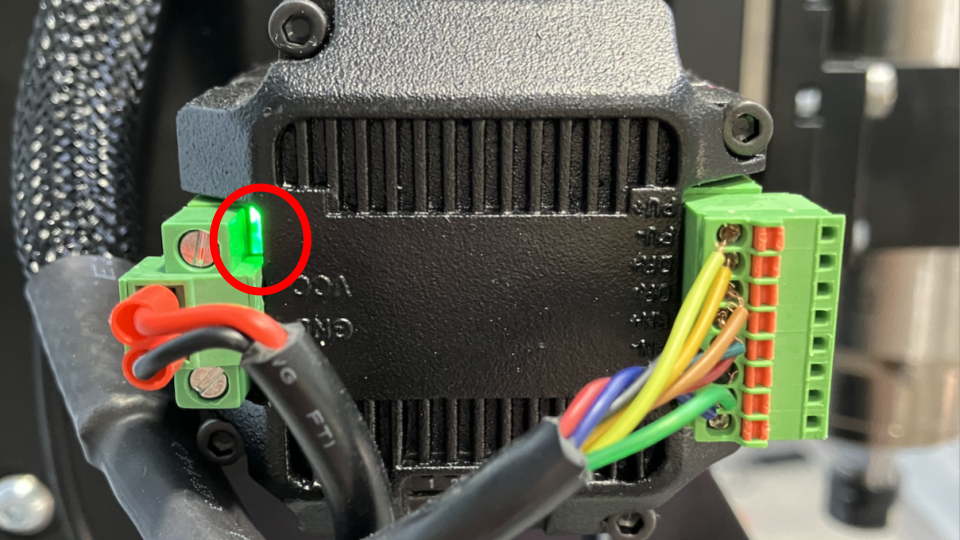

1. Is the motor getting power? Check that a small green LED is illuminated near the two pin power connector on the back of the motor. Also try turning the motor – you should not be able to.

Solid green light at motor power connector

2. If you see an occasional red light on the motor, and you are able to spin the motor shaft by hand, then the machine is in an alarm state. Power cycle the machine to reset this.

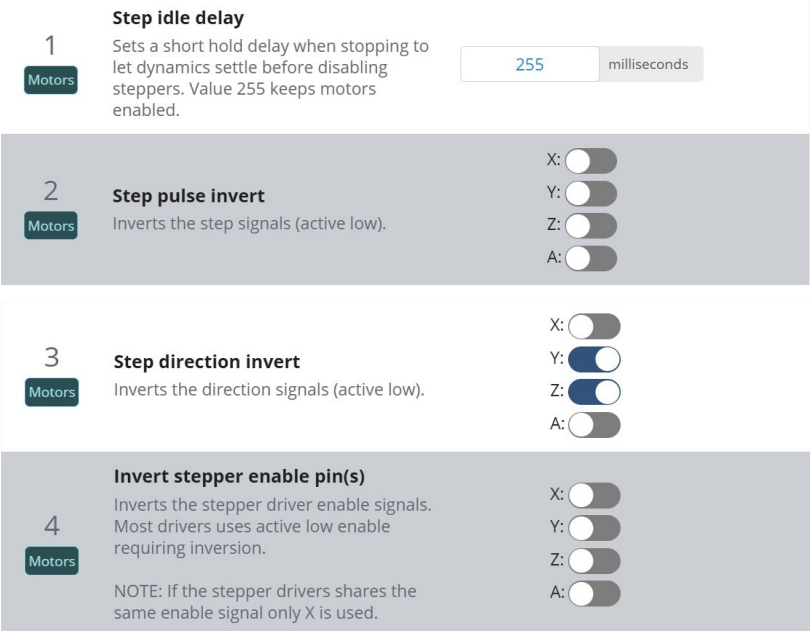

3. Make sure that the settings in the ‘Firmware’ tool on gSender match the following toggles in the photo.

Default correct settings on gSender ($1=255, $2=0, $4=0)

Default correct settings on gSender ($1=255, $2=0, $4=0)

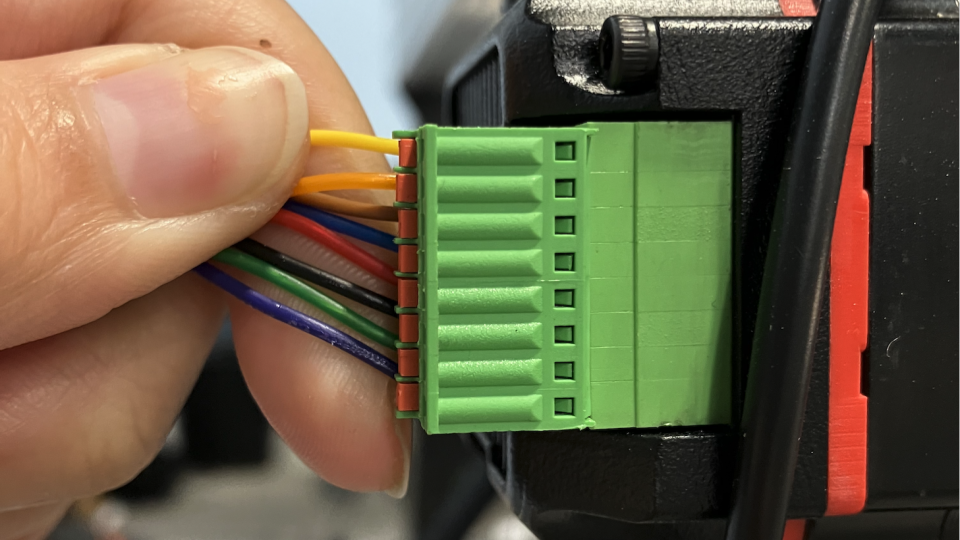

4. Check that the 8 pin connector going to the motor has all of its connections intact and are not loose. To insert wire into each terminal use a small flat screwdriver to press down on the orange tab to open the terminal. Tug wires to check they are secured.

Secured wires at 8 pin connector on motor