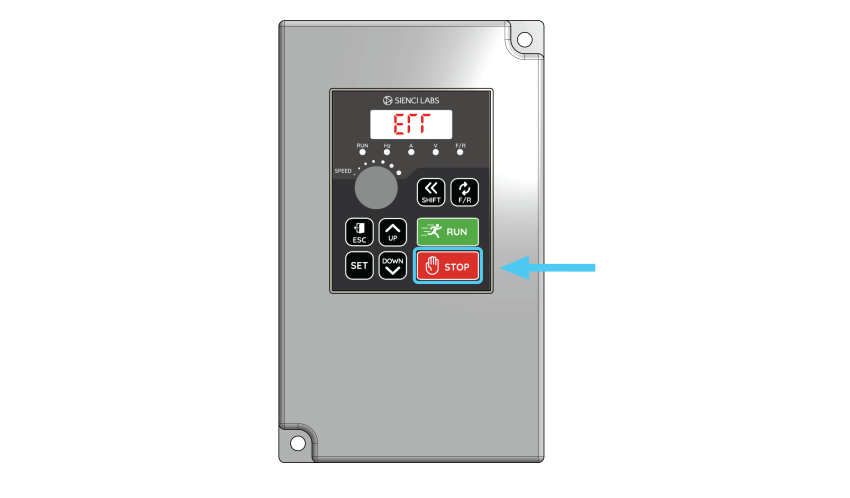

Spindle is not operational after stalling

In the event the spindle stalls due to an overly aggressive toolpath, or gcode/programming error, the VFD will enter a fault state to protect from damaging any electronics. To re-enable the spindle system, simply press the small red ‘STOP’ button on the front panel of the VFD unit and the system will be instantly re-enabled and ready to go.

r00.0 on VFD or Alarm 14 on gSender

The controller is not communicating with the VFD correctly.

1. Download the setup file Sienci_Spindle_Configuration__SLB-EXT_

2. Open gSender and run the attached setup code. This will set all EEPROM settings to what they should be

3. Power cycle everything. Turn off the VFD and the controller. Close gSender

4. Turn on the VFD first, then the controller, then connect to gSender.

5. Ensure the VFD is plugged into the back of the controller above the power switch.

6. Go to console, type $spindles and check if H100 is selected as “Current spindle”.

7. In Console, type M3S10000 to see if the spindle spins properly.

8. In Console, type M5 to see if the spindle stops.

Spindle only spins up to 7500 RPM (readout on VFD will show 125hz)

This is caused by a bug when first enabling RS485 control. Power cycle the SLB-EXT using the slide switch, then unplug and replug the VFD power cord.