Table Surface

The AltMill is designed to use a sheet of MDF as the surface of our table. Furthermore, we will also need a wasteboard (also known as a spoilboard), which acts as a replaceable top layer for material stock to be mounted on during machining. We recommend mounting a separate wasteboard (like a set of slats or a full sheet) onto our MDF table surface, however it is possible to use this MDF table surface as the wasteboard itself.

First, you will need at least one 4’x8’ sheet of ¾” thick MDF. Cut this down in length to 51.75” – this will be the table surface.

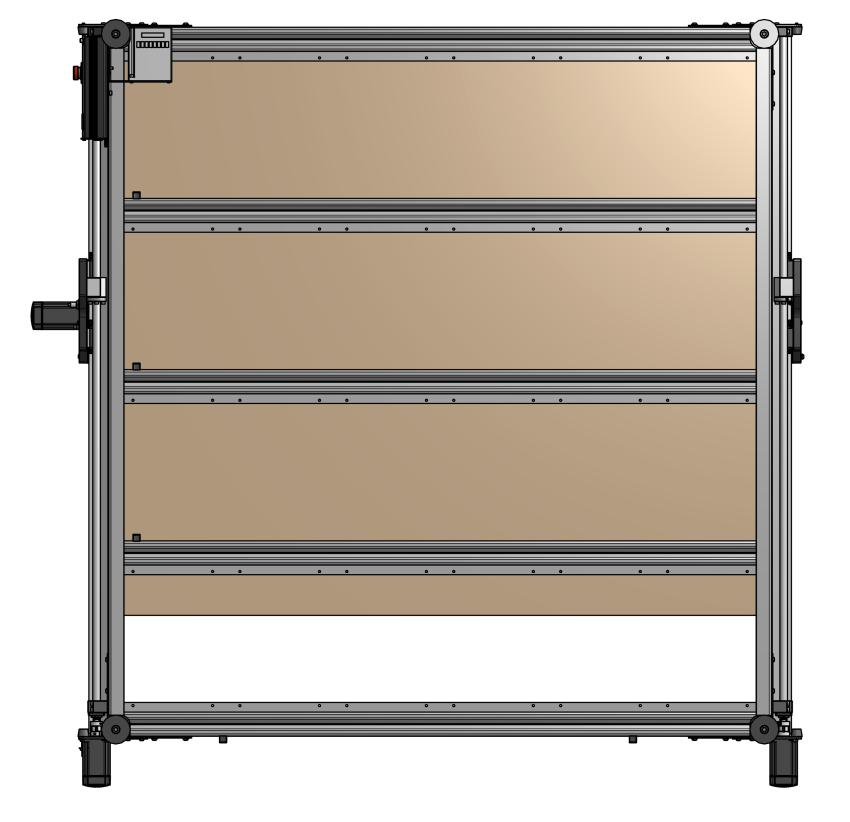

Lay this MDF sheet onto the top of the table frame on the AltMill, filling the entire width of the frame, while lining up the front edge of the sheet with the front of the machine.

Underside view of table, with MDF sheet lined up to the front edge of table

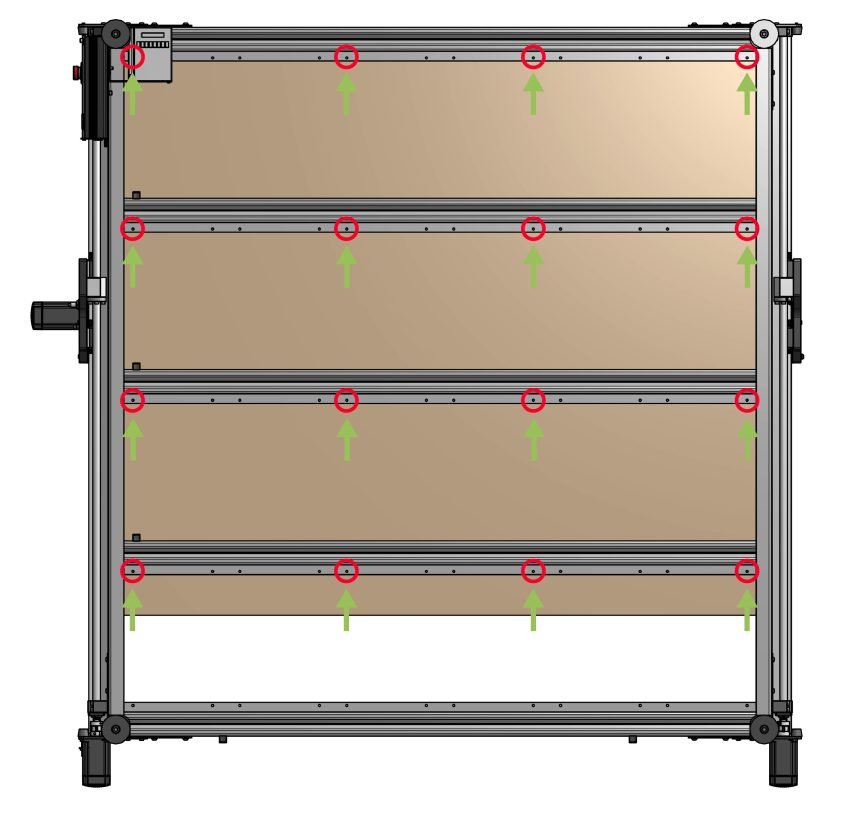

From underneath the table frame, install ¾” long #6 or #8 wood screws through the holes in each crossbeam and into the MDF sheet. There are many holes here that exist for supporting future T-track systems, but you may choose to use the four (4) holes per crossbeam as shown.

Underside view of table, indicating crossbeam holes

At this point, you can either:

- Install the Sienci Labs T-track set alongside MDF slats, which will act as your wasteboard

- Add a sacrificial top sheet to use as your wasteboard

- Skip to ‘surfacing’ where you would machine directly onto the single sheet of MDF without any sacrificial top sheet to create a flat working surface (not recommended).

T-track Installation

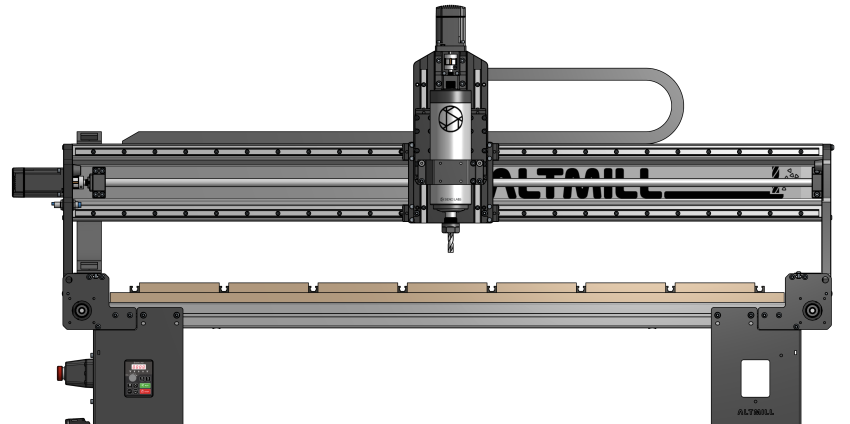

If you are installing the T-track set as part of your wasteboard, take the remainder of your 4’x8’ sheet of MDF that was previously cut, which should measure about ~44”x48”. Cut this extra material into seven (7) ‘slat’ pieces that are ~6.125” wide. These will be placed in between each of the eight (8) T-tracks. Lay all 7 slat pieces and 8 T-track sections onto your table surface, lining these up with the front edge of the table.

Front view of machine with slats and T-tracks placed on table surface

Use ¾” long #6 or #8 wood screws to secure the T-tracks, and 1 ¼“ long #6 or #8 wood screws to secure the slats into the MDF table surface. You’ll want to create a recess in each slat for the heads of the wood screws, so that they sit below the top surface, as we will be surfacing these slats later on. Typically, 8 screws will be used on each slat but this may vary for your setup.

Once finished, you’re ready to move on to surfacing so that your projects sit flat on your machine!

Sacrificial Sheet Setup

If installing a plain sheet of MDF to use as your wasteboard, you can either reuse the remaining 44”x48” sheet of MDF, which will reduce the working surface area of your machine to that size, or you can recut a 48”x48” wasteboard sheet from a new piece of MDF, and keep the other half as a replacement for later. If cutting a new sheet, you may choose to use ½” thick MDF since this is a bit cheaper and easier to transport.

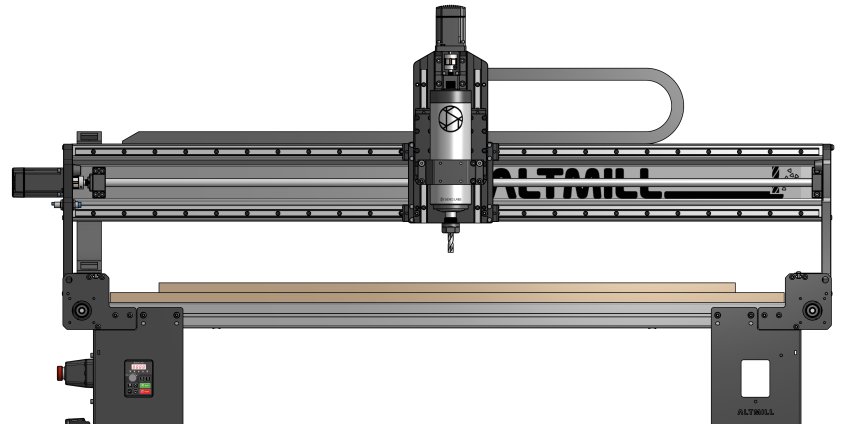

Front view of machine with remaining 44″x48″ MDF sheet

Lay this MDF sheet onto the table, and secure this with wood screws placed in a grid pattern – typically 16 screws will be adequate but this may depend on how warped the MDF you have is. Be sure to recess the heads of each screw below the surface of the MDF since we’ll be machining the top surface of these slats.

Once finished, you’re ready to move on to surfacing so that your projects sit flat on your machine!

Surfacing

Surfacing is simply the process of ‘flattening’ your AltMill wasteboard setup. Flattening is in quotes because we’re not actually making a true flat surface with this process, instead we’re trying to make a surface that’s parallel to the CNC. This is important because when you tell it to cut a 1mm deep circle into your material, you’d want it to be 1mm deep at all points along that circle, not deeper in some areas and shallower in others.

Surfacing can also:

- Eliminate warp or bumps in the material being used as your wasteboard

- Be used for maintenance purposes to clean off old marks and scars and leave you with a new, clean surface to glue, clamp, and mount your material to

When surfacing, you will want a cutting tool specific to this process, called a surfacing bit. These are made for light passes but are usually larger in diameter, so they can cover a large area quickly while leaving a good surface finish. Larger bits can also reach further outside the cutting area of the machine. We typically use the 22mm surfacing bit we sell on our store. If you don’t have one of these, it’s still possible to flatten your wasteboard with something as small as a 1/4″ but it will take much longer to process your whole cutting area.

To generate the g-code/program for running surfacing on your machine, power on your machine and connect to it in gSender, our machine interface software. In gSender, click on the ‘Surfacing’ button to open the surfacing tool. Here, you’ll see a variety of settings that we’ll use to generate our desired surfacing program.

X & Y: You will want this as the same dimensions of your wasteboard. This will typically be about 49” (1245mm) in the X and 48” (1220mm) in the Y.

Cut Depth: It’s best to usually keep this as 1mm or less, cutting any deeper with a large bit can result in an uneven surface

Max: Aka the max depth, which will dictate the total depth of cut into your wasteboard. This is normally set to 1mm. Greater depth is necessary if your board is very warped or has deep imperfections. If the max depth and step down are set to the same value, the machine will perform only one surfacing pass at a single depth.

Stepover: about 40% overlap, close passes (larger step over) will result in a longer cutting time and a smoother finish, whereas far passes may result in a rougher finish

Spindle RPM: A speed setting of around 20,000 RPM works well for MDF and other woods.

Feedrate: Setting your feed rate to ~8000 mm/min should be suitable for the AltMill cutting MDF, however running this slower may produce a slightly nicer finish.

Once you decide on your settings you can click ‘Generate G-code’ to view the path and then click ‘Run on Main Visualizer’ to load the file onto gSender. Then you can start running it just like a regular g-code file!

This video below outlines the steps of surfacing your wasteboard using gSender, however make sure to use the AltMill-specific settings as indicated above.