Maintenance is a critical part of achieving optimal machine operation. The tasks below are especially important for those who use their AltMill everyday, at high speeds, and for long periods of time.

Just like changing oil in your car, service intervals will ultimately depend on the amount of distance your AltMill has traveled rather than some arbitrary amount of time.

In addition, the AltMill should be regularly checked for loose parts, irregular sounds and foreign objects including large buildups of dust or chips that could block moving components. Staying alert and noticing any changes to your machine over time will inform your maintenance routine, keeping it in tip top shape.

Materials needed

- Mobil Vactra No. 2 oil or 3-in-1 oil

- Mobil EP 2 grease or NLGI #2 lithium grease

- Blunt syringe or pipette, to apply oil

- Grease gun, with an assortment of fittings and at least a 12” length flexible whip hose

- Shop towels

- Scotch Brite

- Soft toothed brush, to get into crevices

Linear guides lubrication

Frequency

Every 100km of distance run by the blocks. So faster cutting and longer runtimes require more maintenance.

- At the highest recommended cutting speed (12,000mm/min or 500 IPM) you would need to re-oil every 140 hours of use

- At a much more reasonable lower cutting speed (6,000mm/min or 250 IPM) you would need to re-oil every 280 hours of use

Since a CNC router is subject to wildly varying conditions and types of use cases, these recommended numbers should be taken more as a general recommendation, not as hard deadlines or fixed intervals.

Method

Clean – Wipe down the guide rails with shop towel to remove debris. If there is rust, scrub down with Scotch Brite. Jog the machine to access the entire rail for thorough cleaning.

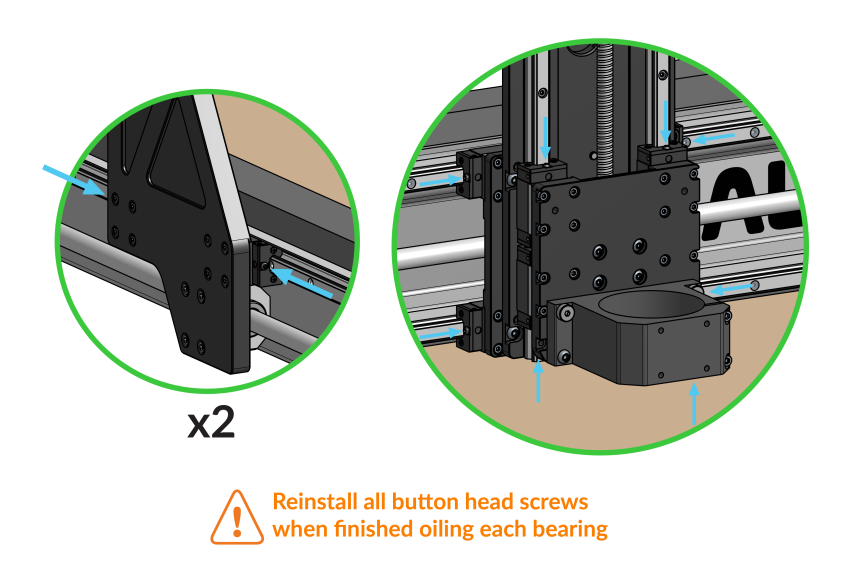

Lubricate – Unfasten the outer button head screw from each linear guide block. Apply the oil using a pipette or syringe to the hole until it flows out. Then refasten the screw. Additionally, you could instead manually coat the linear guide rails with shop towel.

Jog the machine along the axis to distribute the lubricant. Each block should be accessible without disassembly of the machine. The number of blocks on each axis are listed below.

- X-axis: 4

- Y-axis: 2 on each side

- Z-axis: 4

Ball screw lubrication

Frequency

It is recommended that you do maintenance on ball screws at the same time as the linear guide blocks, because they will need re-lubrication at a similar rate.

Method

Clean – Remove debris from the ball screw by using a soft brush (like an old toothbrush) to get into the threads. Make sure you clean the entire ball screw, by jogging the AltMill to another spot.

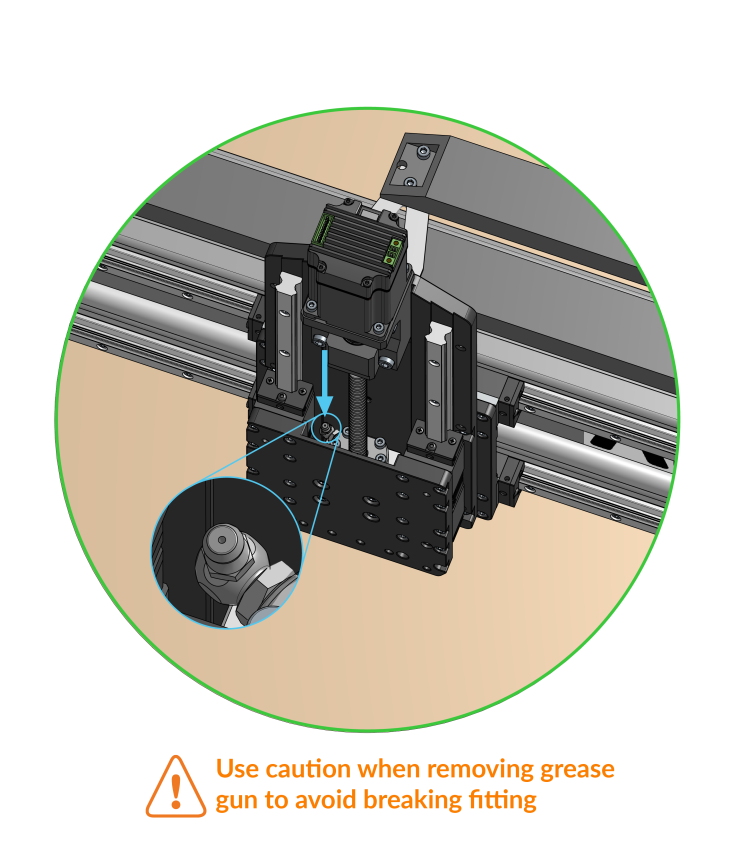

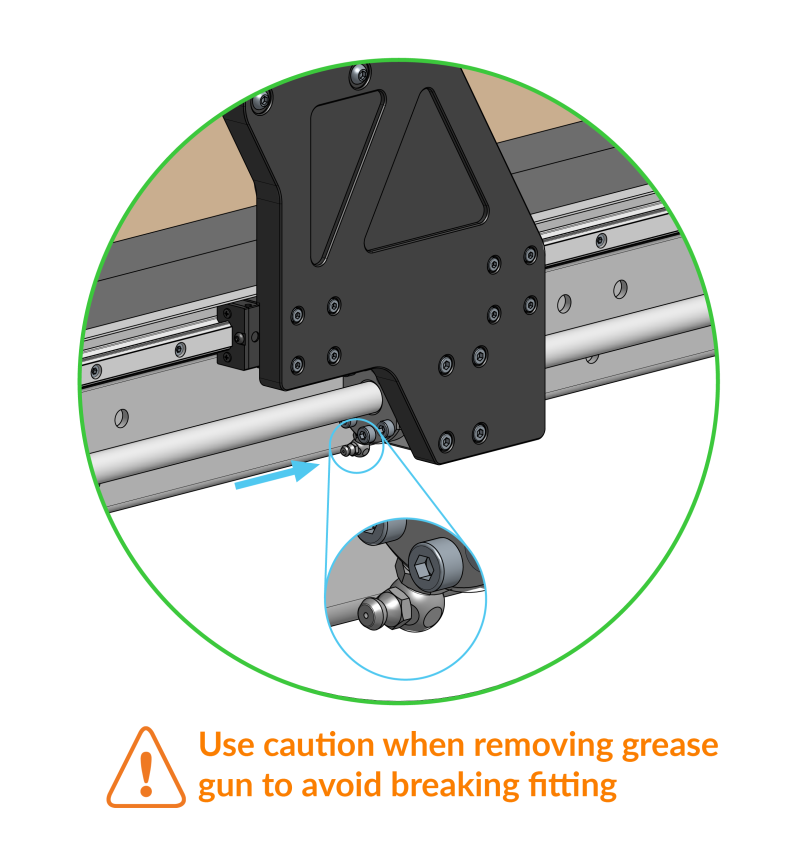

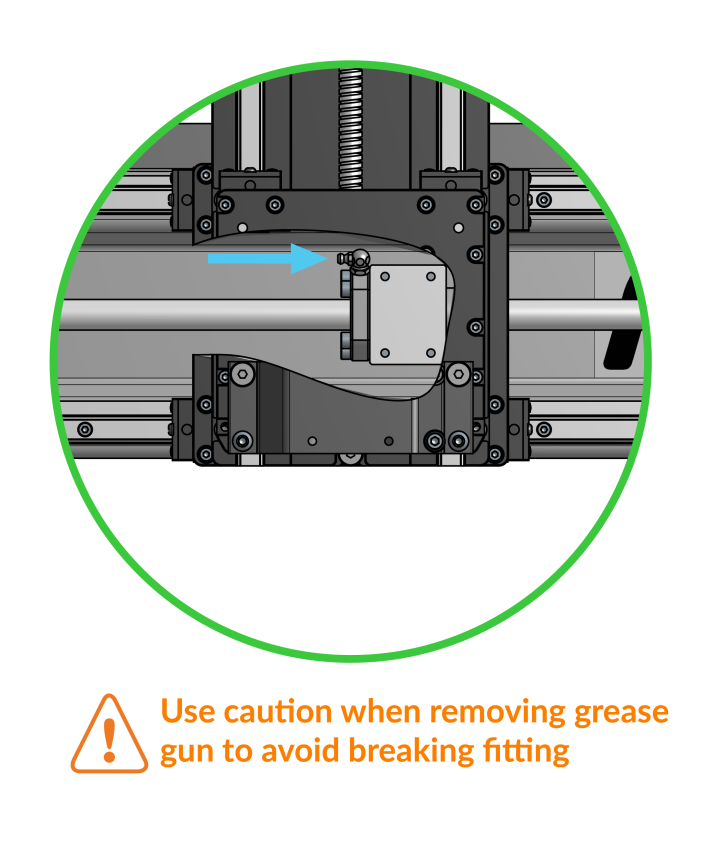

Lubricate – Apply grease at the zerk fitting, using the grease gun. You should only add a small amount, so 1 squeeze at the gun will be enough.

- On the Y-axis, you should be able to easily access the fitting on each side

- On the X-axis and Z-axis, you will need to use a long grease gun fitting and the whip hose

Given the correct hose length and grease gun fitting, you will not need to disassemble the machine unless the fitting is in the wrong orientation. If so: Undo the 4 screws that secure the aluminum ball screw nut to the Y-gantry plate. Then slide the ball screw out from behind, you should be able to access the grease fitting then.

Once you apply the grease, jog the machine along the axis to distribute it.

Z-axis Zerk fitting location accessed from top of the machine

Y-axis Zerk fitting accessed from left and right sides under the machine table

X-axis Zerk fitting accessed from behind the XZ-axis assembly

Spindle

For regular maintenance of your spindle, we recommend running a shorter “warm up” g-code especially if you run your machine in a cold environment. This will help redistribute the grease in the bearings.

Just download the file and run it like you run other jobs. The machine will not move, only the spindle will spin a bit.